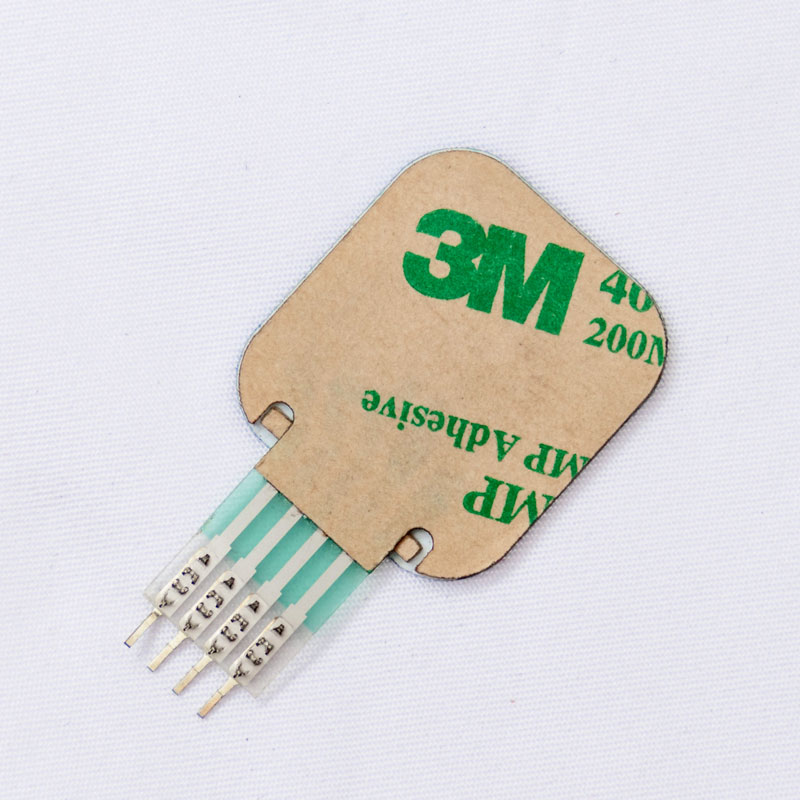

Membrane switches are essential components of modern electronic devices that require user input. These switches are composed of several layers, including a graphic overlay, a spacer layer, a circuit layer, and a rear adhesive layer. The rear adhesive layer is responsible for securing the membrane switch to the device's housing, and its selection is crucial for the switch's performance and durability. In this article, we will explore the different types of adhesives used in membrane switches and the factors to consider when selecting the most suitable adhesive for your application.

Before diving into adhesive selection, let's first understand what membrane switches are and how they work. A membrane switch is a type of momentary switch that uses a thin, flexible membrane as the interface between the user and the device. The membrane is made of a flexible material, such as polyester or polycarbonate, and has conductive traces printed on it using various printing techniques. When a user presses on the membrane, the conductive traces make contact, closing the circuit and sending a signal to the device.

Membrane switches are widely used in electronic devices such as remote controls, medical devices, industrial control panels, and consumer electronics. They offer several advantages over traditional mechanical switches, such as lower cost, reduced size, and increased durability.

The rear adhesive layer is an essential component of the membrane switch, as it secures the switch to the device's housing. The adhesive's selection is critical for the switch's performance and durability, as it must withstand environmental factors such as temperature, humidity, and vibration.

There are several types of adhesives used in membrane switches, including pressure-sensitive adhesives (PSAs), acrylic adhesives, and epoxy adhesives. Each type has its advantages and disadvantages, and selecting the most suitable adhesive depends on several factors, such as the application's requirements, the environment, and the substrate's characteristics.

PSAs are the most common type of adhesive used in membrane switches. They are easy to apply, have an excellent initial tack, and require no curing time. PSAs work by creating an immediate bond between the adhesive and the substrate, usually a plastic or metal surface.

PSAs come in different formulations, such as rubber-based, acrylic-based, and silicone-based. Each formulation has its characteristics, such as temperature resistance, chemical resistance, and bonding strength. Rubber-based PSAs are the most cost-effective and have good bonding strength, but they are not suitable for high-temperature applications. Acrylic-based PSAs have better temperature and chemical resistance, but they are more expensive than rubber-based PSAs. Silicone-based PSAs have the best temperature and chemical resistance, but they are the most expensive and difficult to handle.

Acrylic adhesives are another type of adhesive used in membrane switches. They have excellent temperature and chemical resistance and are suitable for high-performance applications. Acrylic adhesives work by creating a chemical bond between the adhesive and the substrate, which requires curing time and proper surface preparation.

Acrylic adhesives come in different formulations, such as solvent-based, water-based, and 100% solids. Solvent-based acrylics are the most common and offer good bonding strength and temperature resistance. Water-based acrylics are eco-friendly and have low VOC emissions but require longer curing time. 100% solids acrylics offer the best chemical resistance and bonding strength, but they are expensive and require specialized equipment for application.

Epoxy adhesives are the most durable and high-performance adhesives used in membrane switches. They have excellent chemical resistance, bonding apacity, and temperature resistance, making them ideal for harsh environments. Epoxy adhesives work by creating a chemical bond between the adhesive and the substrate, which requires curing time and proper surface preparation.

Epoxy adhesives come in two parts, a resin and a hardener, which are mixed before application. The curing time and temperature depend on the epoxy's formulation and the application's requirements. Epoxy adhesives are the most expensive and require specialized equipment for application, but they offer the best durability and performance.

Selecting the most suitable adhesive for a membrane switch depends on several factors, such as the application's requirements, the environment, and the substrate's characteristics. Here are some factors to consider when selecting an adhesive for your application:

Temperature

Temp erature is a crucial factor to consider when selecting an adhesive for a membrane switch. The adhesive must withstand the application's operating temperature range without losing its bonding strength or changing its properties. Rubber-based PSAs are suitable for low-temperature applications, while acrylic and epoxy adhesives are suitable for high-temperature applications.

Chemical Resistance

Chemical resistance is another factor to consider when selecting an adhesive for a membrane switch. The adhesive must resist the chemicals that the application is exposed to without losing its bonding strength or changing its properties. Silicone-based PSAs and 100% solids acrylic adhesives offer the best chemical resistance.

Bonding Strength

Bonding strength is a critical factor to consider when selecting an adhesive for a membrane switch. The adhesive must have enough bonding strength to hold the switch to the substrate without peeling or delaminating. Rubber-based PSAs offer good bonding strength, while acrylic and epoxy adhesives offer better bonding strength.

Substrate

The substrate's characteristics, such as its surface energy, roughness, and material, are important factors to consider when selecting an adhesive for a membrane switch. The adhesive must bond well to the substrate without losing its bonding strength or changing its properties.

Selecting the most suitable adhesive for a membrane switch is crucial for its performance and durability. Pressure-sensitive adhesives, acrylic adhesives, and epoxy adhesives are the most common types of adhesives used in membrane switches, each with its advantages and disadvantages. When selecting an adhesive, consider factors such as temperature, chemical resistance, bonding strength, and substrate characteristics to ensure the best performance and durability.

What is a membrane switch?

A membrane switch is a type of momentary switch that uses a thin, flexible membrane as the interface between the user and the device.

What is the rear adhesive layer in a membrane switch?

The rear adhesive layer is an essential component of the membrane switch, as it secures the switch to the device's housing.

What are the types of adhesives used in membrane switches?

The types of adhesives used in membrane switches include pressure-sensitive adhesives, acrylic adhesives, and epoxy adhesives.

What factors should I consider when selecting an adhesive for a membrane switch?

When selecting an adhesive for a membrane switch, consider factors such as temperature, chemical resistance, bonding strength, and substrate characteristics.

Which adhesive is the most suitable for a high-temperature application?

Acrylic and epoxy adhesives are suitable for high-temperature applications.