Membrane switches are an integral part of many electronic devices. They are a type of interface that allows the user to interact with the device by pressing on the switch. A membrane switch consists of several layers of materials that are assembled in a specific order to create the switch. In this article, we will take a closer look at how membrane switches are manufactured, the materials used in their construction, and the different types of membrane switches.

Membrane switches are an essential part of many electronic devices. They are used in everything from consumer electronics to industrial equipment. Membrane switches are typically designed to be easy to use, reliable, and durable. They can be customized to fit the specific needs of the device they are being used in. In this article, we will take a closer look at how membrane switches are manufactured.

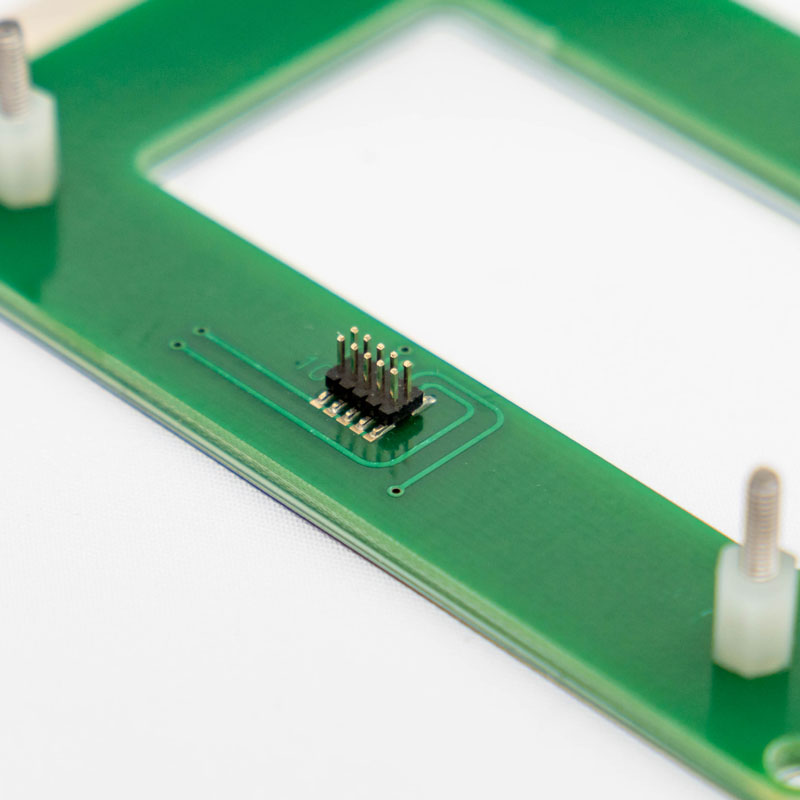

A membrane switch is a type of switch that is made up of several layers of material. It typically consists of a graphic overlay layer, adhesive layer, circuit layer, spacer layer, and a backer layer. When the user presses on the switch, the layers of the switch are compressed, causing the circuit to close and completing the electrical connection.

There are several different materials used in the construction of a membrane switch. Each layer of the switch serves a specific purpose and is made up of a different material.

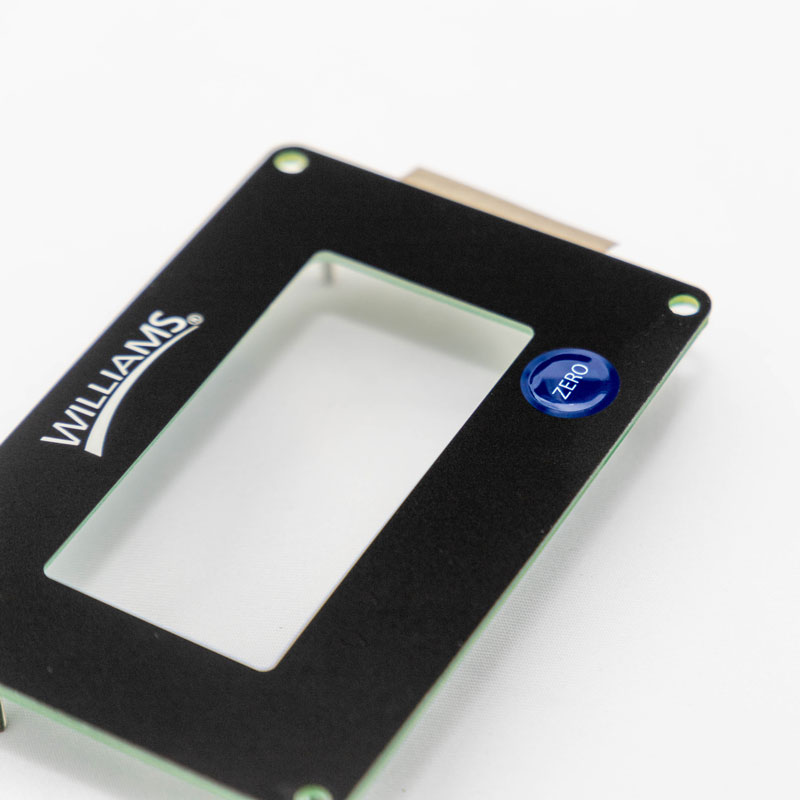

* Graphic overlay

The graphic overlay is the top layer of the membrane switch. It is typically made of a polyester or polycarbonate material and is printed with the design of the switch.

* Adhesive layer

The adhesive layer is used to attach the graphic overlay to the circuit layer. It is typically made of a pressure-sensitive adhesive material.

* Circuit layer

The circuit layer is the layer that contains the electrical connections of the switch. It is typically made of a copper or silver material that is printed onto a polyester substrate.

* Spacer layer

The spacer layer is used to provide space between the circuit layer and the backer layer. It is typically made of a polyester material and is used to create the tactile response of the switch.

* Backer layer

The backer layer is the bottom layer of the membrane switch. It is typically made of a polyester or polycarbonate material and is used to provide support for the switch.

The manufacturing process of a membrane switch typically consists of several different steps. These steps include design and engineering, printing the graphic overlay, creating the circuit layer, laminating the layers, and die-cutting and finishing.

* Design and engineering

The first step in the manufacturing process is designing and engineering the membrane switch. This involves determining the size and shape of the switch, as well as the placement of the electrical connections.

* Printing the graphic overlay

Once the design has been finalized, the graphic overlay is printed. This is typically done using a digital printing process that allows for high-resolution images and fine details.

* Creating the circuit layer

The circuit layer is created next. This involves printing the circuit pattern onto a polyester substrate using a copper or silver conductive ink. The circuit pattern is designed to provide the necessary electrical connections for the switch.

* Laminating the layers

Once the graphic overlay and circuit layer have been printed, they are laminated together with the adhesive layer and spacer layer. This process involves using heat and pressure to bond the layers together.

* Die-cutting and finishing

After the layers have been laminated together, the switch is die-cut into the desired shape. This involves cutting through all the layers of the switch to create the final shape. The switch is then finished by adding any necessary embossing, texturing, or printing to the surface of the switch.

There are two main types of membrane switches: tactile and non-tactile switches.

Tactile membrane switches are designed to provide feedback to the user when the switch is pressed. They typically have a dome-shaped button that compresses when the switch is pressed, providing a tactile response.

* Non-tactile membrane switches

Non-tactile membrane switches do not provide any feedback to the user when the switch is pressed. They typically have a flat surface and require less force to activate than tactile switches.

Membrane switches offer several advantages over other types of switches. They are typically more durable and reliable than mechanical switches, as they have no moving parts that can wear out. They are also easy to clean and sanitize, making them ideal for use in medical and food processing equipment. Additionally, membrane switches can be customized to fit the specific needs of the device they are being used in.

Membrane switches are an essential part of many electronic devices. They are made up of several layers of material that are assembled in a specific order to create the switch. The manufacturing process involves several steps, including designing and engineering, printing the graphic overlay, creating the circuit layer, laminating the layers, and die-cutting and finishing. There are two main types of membrane switches: tactile and non-tactile switches. Membrane switches offer several advantages over other types of switches, including durability, reliability, and customization.

What is a membrane switch used for?

A membrane switch is used as an interface between the user and an electronic device, allowing the user to input commands by pressing on the switch.

What materials are used to make a membrane switch?

A membrane switch is made up of several layers of material, including a graphic overlay, adhesive layer, circuit layer, spacer layer, and backer layer.

What is the difference between a tactile and non-tactile membrane switch?

A tactile membrane switch provides feedback to the user when the switch is pressed, while a non-tactile switch does not.

Are membrane switches durable?

Yes, membrane switches are typically more durable and reliable than mechanical switches, as they have no moving parts that can wear out.

Can membrane switches be customized?

Yes, membrane switches can be customized to fit the specific needs of the device they are being used in.