Membrane Switches in Defense

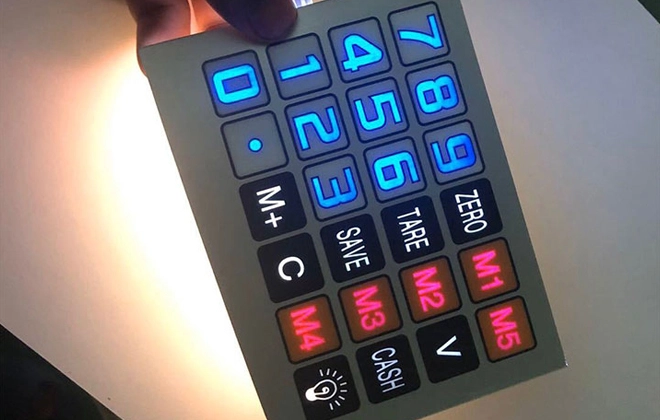

Some of the membrane switches sold by Niceone-tech abroad are used in military manufacturing. Because military products have strict requirements for membrane switches, there can be no mistakes.

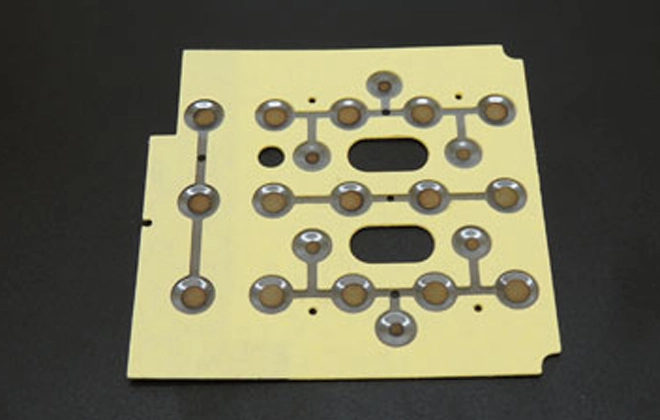

The components installed in the membrane switch circuit may need to use a Flex printing circuit (FPC) or PCB. This type of circuit is more durable and can withstand more extreme temperatures. At the same time, the components assembled in the FPC and PCB circuit will be more durable and can Resistant to high-frequency vibration, low resistance, etc. If you want to design products for military applications, you need to consider many aspects when developing its membrane switch user interface:

The product life needs to be longer and the response is more sensitive:

In many cases, a high-quality membrane switch needs to be affected by many factors. The life of shrapnel, the choice of tape, the life of LEDs. Line selection, ink adhesion, etc. A good shrapnel life can reach 5,000,000 times. Good adhesive tape is similar to 3M adhesive tape and can be used at -20 degrees. The adhesion of the ink will affect the circuit and the panel. A good ink can pass the 100 grid test and will not drop due to a slight collision. The choice of panel material allows the membrane switch to adapt to different application environments. XE material can make the product resist ultraviolet rays. EBG material is very scratch resistant. At the same time, the copper flexible circuit on the polyimide is much more durable than the screen-printed polyester silver ink.

English

English français

français Deutsch

Deutsch Español

Español italiano

italiano português

português dansk

dansk Suomi

Suomi Polska

Polska Svenska

Svenska Nederland

Nederland