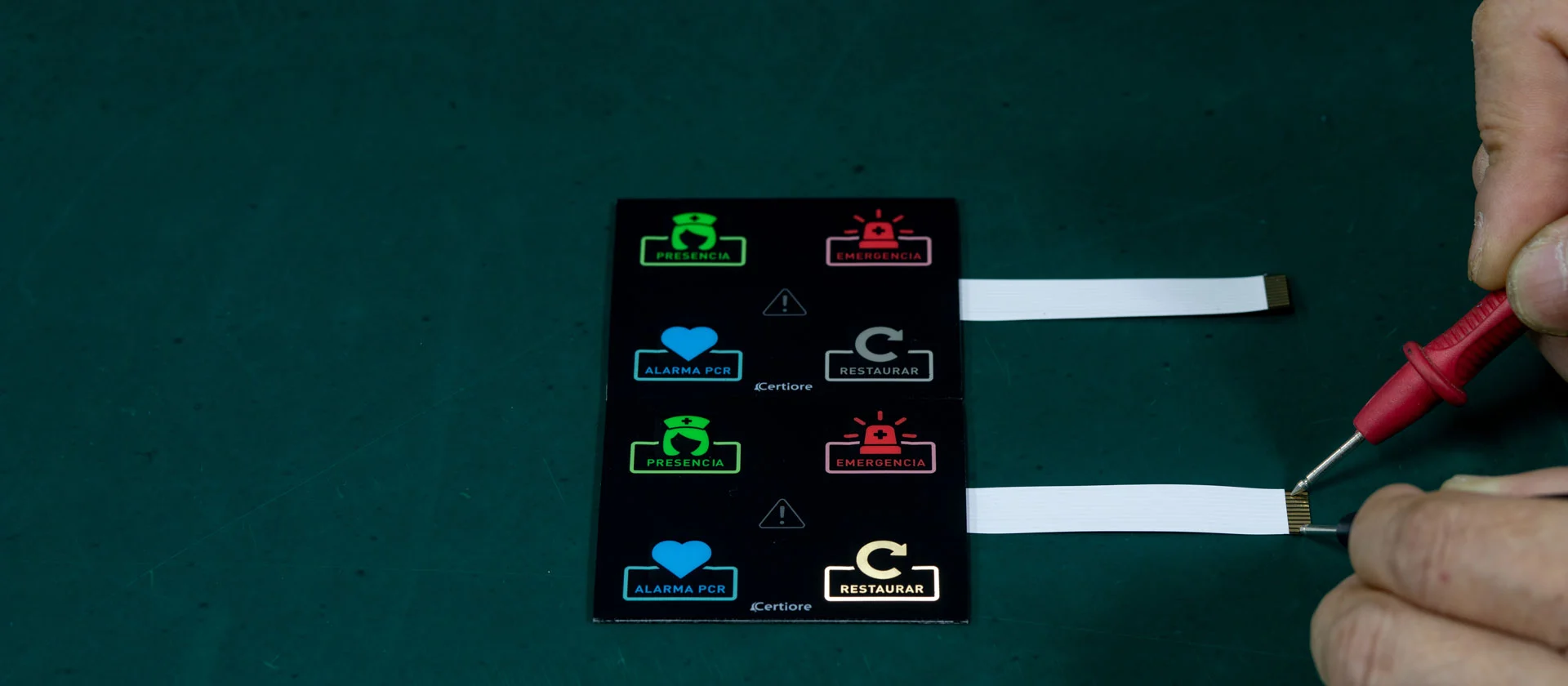

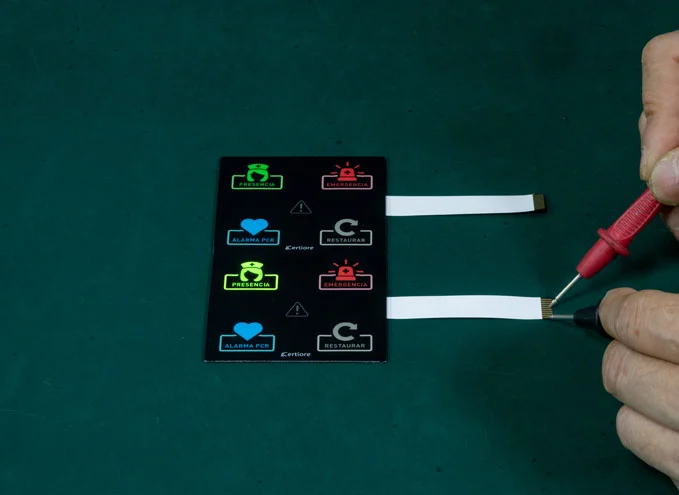

Membrane switches are essential electronic components for many household products, medical products and even military equipment. Membrane switches can also be called membrane keypads and membrane panels. More often, the membrane switch is a customized product, so how to design an excellent custom membrane keypad has always been the mainstream melody of the industry.

Fortunately, Niceone-tech has more than 20 years of experience in this industry and can customize membrane switches that best suit customers' needs. If you have detailed drawings, then our project will analyze whether the drawings can be customized for production, and whether it is necessary to adjust some material structure, color matching, button load, etc. If it's just an idea, Niceone-tech will do our best to help customers realize their drawings and meet their needs. Niceone-tech is very grateful to our customers for their trust. Customers from different industries have cooperated with us.

THERE ARE MANY ADVANTAGES OF CUSTOMIZATION

Color autonomy.

The shape of the product like the membrane keypad and China rubber keypad can be formed into a corresponding appropriate shape according to the product.

Can choose different materials according to the application environment to meet customer needs.

English

English français

français Deutsch

Deutsch Español

Español italiano

italiano português

português dansk

dansk Suomi

Suomi Polska

Polska Svenska

Svenska Nederland

Nederland