The medical industry has been relying on the advancements in technology for better diagnosis and treatment of patients. The integration of technology in the medical equipment has made the job of medical professionals much easier, accurate and efficient. One such technological innovation is the LED membrane switch that has revolutionized the way medical equipment is designed and operated. In this article, we will discuss what factors should be considered when using LED membrane switches in medical equipment.

Definition of LED membrane switch

Significance of LED membrane switch in medical equipment

Importance of design in medical equipment

Factors to consider in designing LED membrane switches for medical equipment

Size and shape of the switch

Color of the switch

Placement of the switch

Importance of material selection in medical equipment

Considerations for material selection for LED membrane switches in medical equipment

Medical grade materials

Durability and lifespan of the material

Resistance to chemicals and sterilization

Importance of electrical specifications in medical equipment

Considerations for electrical specifications for LED membrane switches in medical equipment

Voltage rating

Current rating

Power consumption

ESD protection

Importance of environmental factors in medical equipment

Considerations for environmental factors for LED membrane switches in medical equipment

Temperature range

Humidity range

Resistance to moisture and water

Shock and vibration resistance

Importance of compliance in medical equipment

Considerations for compliance for LED membrane switches in medical equipment

ISO certifications

FDA regulations

CE marking

RoHS compliance

Importance of cleaning and maintenance in medical equipment

Considerations for cleaning and maintenance of LED membrane switches in medical equipment

Cleaning procedures

Sterilization procedures

Frequency of cleaning and maintenance

Importance of user interface in medical equipment

Considerations for user interface of LED membrane switches in medical equipment

Button layout and labeling

Tactile feedback

User-friendly interface

Importance of reliability in medical equipment

Considerations for reliability of LED membrane switches in medical equipment

MTBF (Mean Time Between Failures)

Failure modes and effects analysis (FMEA)

Redundancy

The use of LED membrane switches in medical equipment has become common due to their advantages over traditional mechanical switches. However, several factors need to be considered to ensure that these switches meet the requirements of medical equipment in terms of design, material, electrical specifications, environmental factors, compliance, cleaning and maintenance, user interface, and reliability. With proper consideration of these factors, LED membrane switches can be an efficient and reliable component of medical equipment.

1. Can LED membrane switches be used in high-temperature environments?

2. Are LED membrane switches resistant to chemicals and sterilization?

3. What compliance certifications are required for LED membrane switches used in medical equipment?

4. How often should LED membrane switches in medical equipment be cleaned and maintained?

5. Can LED membrane switches be customized according to user requirements?

1. Introduction

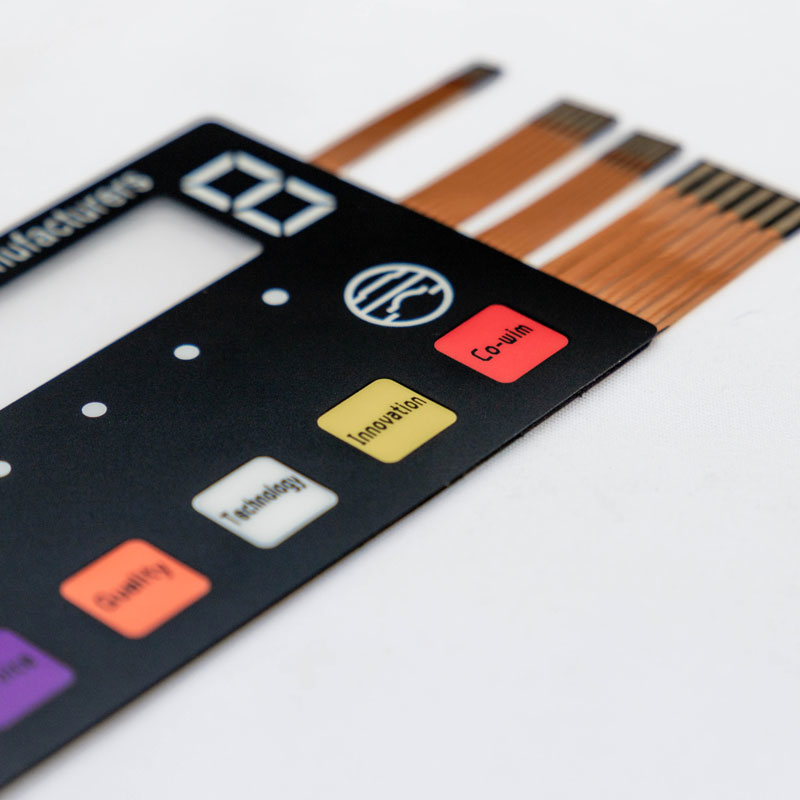

The LED membrane switch is a type of switch that combines a printed circuit board with a flexible membrane layer that contains LED lights. It has become a popular choice for use in medical equipment due to its ability to withstand harsh conditions, such as exposure to chemicals, water, and extreme temperatures. Additionally, LED membrane switches offer a sleek, modern design that is easy to use and maintain.

2. Design

Design is an important consideration when using LED membrane switches in medical equipment. The size and shape of the switch, as well as its color and placement, can impact its usability and efficiency. Additionally, the design must take into account any labeling or buttons that are necessary for the user to operate the equipment effectively.

3. Material

Choosing the right material for LED membrane switches is critical for ensuring their longevity and ability to withstand the conditions of medical environments. Medical-grade materials are typically preferred due to their resistance to chemicals and ability to withstand sterilization. Durability and lifespan of the material should also be considered.

4. Electrical Specifications

Electrical specifications are an important consideration when using LED membrane switches in medical equipment. The voltage rating, current rating, power consumption, and ESD protection should all be taken into account to ensure the switch is operating safely and efficiently.

5. Environmental Factors

Environmental factors, such as temperature, humidity, moisture, and shock resistance, are important considerations for LED membrane switches in medical equipment. These switches must be able to operate effectively in a variety of environments and withstand exposure to harsh conditions.

6. Compliance

Compliance with regulations and certifications is essential for LED membrane switches used in medical equipment. ISO certifications, FDA regulations, CE marking, and RoHS compliance are all important considerations to ensure that the switch meets the necessary safety and quality standards.

7. Cleaning and Maintenance

Cleaning and maintenance are important factors to consider for LED membrane switches in medical equipment. Proper cleaning and sterilization procedures must be followed to ensure the switch remains hygienic and free from contaminants. The frequency of cleaning and maintenance should also be considered to ensure the switch continues to operate efficiently.

8. User Interface

User interface is an important consideration when using LED membrane switches in medical equipment. The button layout and labeling should be intuitive and easy to understand, and the switch should provide tactile feedback to the user. A user-friendly interface can help medical professionals operate the equipment more efficiently and accurately.

9. Reliability

Reliability is a key consideration for LED membrane switches in medical equipment. Mean time between failures (MTBF), failure modes and effects analysis (FMEA), and redundancy should all be considered to ensure the switch operates reliably and efficiently over an extended period of time.

10. Conclusion

In conclusion, LED membrane switches offer many benefits for medical equipment, including durability, sleek design, and easy maintenance. However, careful consideration must be given to factors such as design, material, electrical specifications, environmental factors, compliance, cleaning and maintenance, user interface, and reliability to ensure that the switch is safe, efficient, and reliable for use in medical environments.

11. FAQs

Can LED membrane switches be used in high-temperature environments?

LED membrane switches can be designed to withstand a range of temperatures, but it is important to consider the specific requirements of the medical equipment and environment in which the switch will be used.

Are LED membrane switches resistant to chemicals and sterilization?

Medical-grade materials can be used to make LED membrane switches resistant to chemicals and sterilization, but it is important to select the appropriate material for the specific application.

What compliance certifications are required for LED membrane switches used in medical equipment?

The necessary compliance certifications can vary

depending on the country and region in which the medical equipment will be used, but ISO certifications, FDA regulations, CE marking, and RoHS compliance are commonly required.

How often should LED membrane switches in medical equipment be cleaned and maintained?

The frequency of cleaning and maintenance should be determined based on the specific requirements of the medical equipment and the environment in which it is used. Generally, LED membrane switches should be cleaned and maintained regularly to ensure they remain hygienic and free from contaminants.

Can LED membrane switches be customized according to user requirements?

Yes, LED membrane switches can be customized to meet the specific requirements of the medical equipment and the user interface. This can include the size and shape of the switch, the color of the LED lights, the placement of buttons, and other design features. Working with a trusted manufacturer can ensure that the LED membrane switch is designed and manufactured to meet the unique needs of the medical equipment.