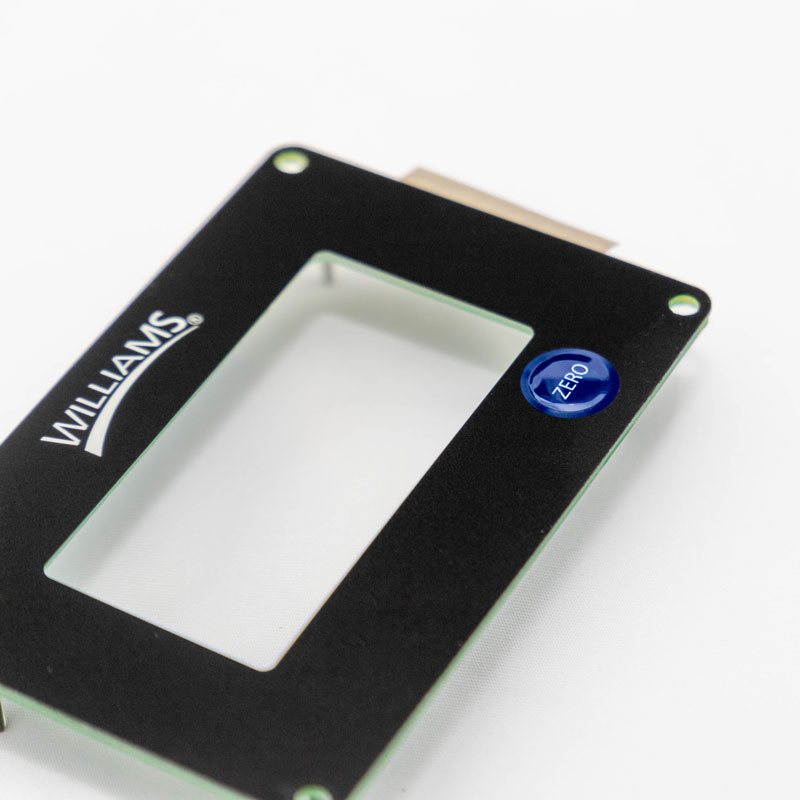

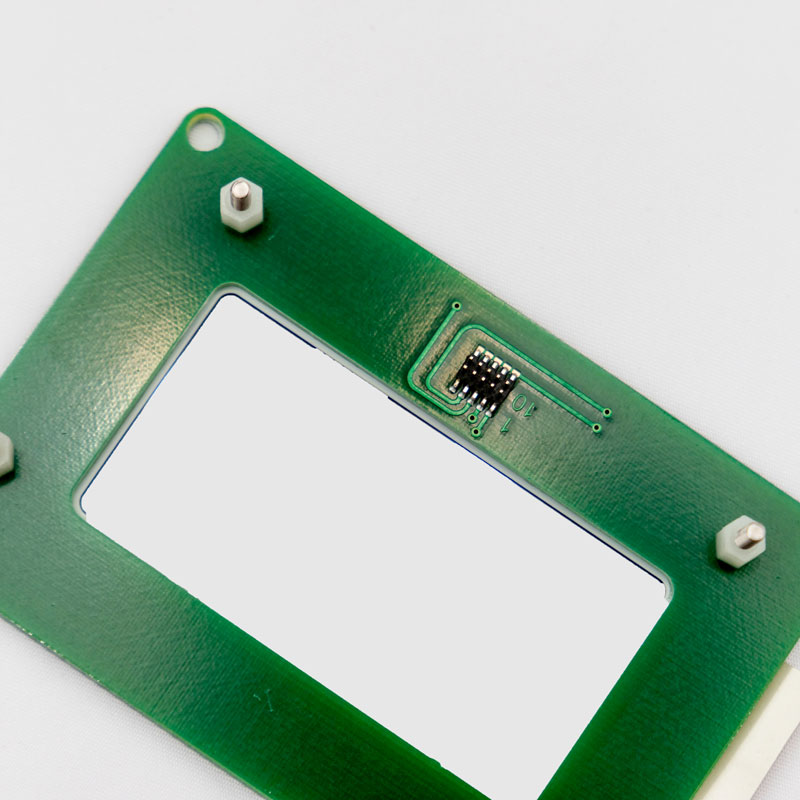

Membrane switches are integral components in many electronic devices, including medical equipment, industrial machines, and consumer products. These switches are thin, flexible, and highly customizable, making them an ideal choice for a wide range of applications. The proper selection of membrane switch materials is critical to ensuring product functionality, durability, and longevity. In this article, we will discuss the importance of membrane switch material selection, the benefits of choosing the right materials, and the potential consequences of selecting the wrong ones.

The materials used in membrane switches must meet specific requirements to ensure proper operation and long-term reliability. These requirements include resistance to environmental factors such as temperature, humidity, and chemical exposure. They must also possess excellent mechanical properties such as tensile strength, tear resistance, and flexibility. The proper selection of materials is critical to the performance of the switch, as well as the device it operates.

Environmental Factors

Environmental factors such as temperature and humidity can significantly impact the performance of membrane switches. The wrong choice of materials can result in switches that malfunction or fail prematurely. Materials that are not resistant to chemicals or moisture can lead to corrosion, delamination, and other forms of degradation. The proper selection of materials can ensure that switches remain functional even in harsh environments.

Mechanical Properties

Membrane switches must also possess excellent mechanical properties to ensure durability and longevity. The materials used must be able to withstand repeated use and bending without cracking or tearing. Tensile strength and tear resistance are essential properties for materials used in membrane switches. The proper selection of materials can ensure that switches remain operational even after prolonged use.

Choosing the right materials for membrane switches can provide numerous benefits, including improved functionality, durability, and cost-effectiveness.

Improved Functionality

The proper selection of materials can significantly improve the functionality of membrane switches. Materials that are highly conductive, for example, can result in switches that respond faster and more accurately to touch. Materials that are highly resistant to wear and tear can ensure switches remain operational even after prolonged use.

Durability

The right materials can significantly improve the durability of membrane switches. Materials that possess excellent mechanical properties, such as tensile strength and tear resistance, can ensure switches remain functional even after prolonged use. Materials that are highly resistant to environmental factors such as temperature and humidity can ensure switches remain operational even in harsh environments.

Cost-Effectiveness

Choosing the right materials can also result in cost savings over the long term. The use of high-quality materials can reduce the need for repairs and replacements, resulting in lower overall costs.

The selection of the wrong materials for membrane switches can result in numerous consequences, including reduced functionality, decreased durability, and increased costs.

Reduced Functionality

The use of materials that are not conductive enough or are too thick can result in switches that do not respond as quickly or accurately to touch. The use of materials that are not resistant to wear and tear can result in switches that fail prematurely.

Decreased Durability

The use of materials that do not possess excellent mechanical properties can result in switches that crack, tear, or delaminate prematurely. The use of materials that are not resistant to environmental factors such as temperature and humidity can result in switches that fail prematurely.

Increased Costs

The use of the wrong materials can result in increased costs due to the need for repairs or replacements. Additionally, the use of low-quality materials can result in reduced product performance, resulting in decreased customer satisfaction and decreased sales.

The proper selection of materials for membrane switches is critical to ensuring product functionality, durability, and longevity. The right materials can significantly improve the functionality and durability of switches while reducing

the need for repairs or replacements. The proper selection of materials can also result in cost savings over the long term. It is important to consider the specific requirements of each application when selecting materials for membrane switches.

What are membrane switches?

Membrane switches are thin, flexible electronic components used in a wide range of devices, including medical equipment, industrial machines, and consumer products.

What factors should be considered when selecting materials for membrane switches?

Factors such as resistance to environmental factors like temperature and humidity, mechanical properties such as tensile strength and tear resistance, and conductivity should be considered when selecting materials for membrane switches.

What are the consequences of selecting the wrong materials for membrane switches?

The consequences of selecting the wrong materials include reduced functionality, decreased durability, and increased costs due to the need for repairs or replacements.

How can choosing the right materials improve the functionality and durability of membrane switches?

Choosing materials with excellent mechanical properties and resistance to environmental factors can improve the functionality and durability of membrane switches.

What are the cost savings associated with choosing the right materials for membrane switches?

Choosing the right materials can result in cost savings over the long term by reducing the need for repairs and replacements.

In conclusion, the selection of the right materials for membrane switches is critical to ensuring their functionality, durability, and longevity. The wrong choice of materials can result in switches that malfunction or fail prematurely, leading to increased costs and reduced customer satisfaction. By considering factors such as environmental resistance and mechanical properties, the right materials can be selected, leading to improved product performance and cost savings over time.