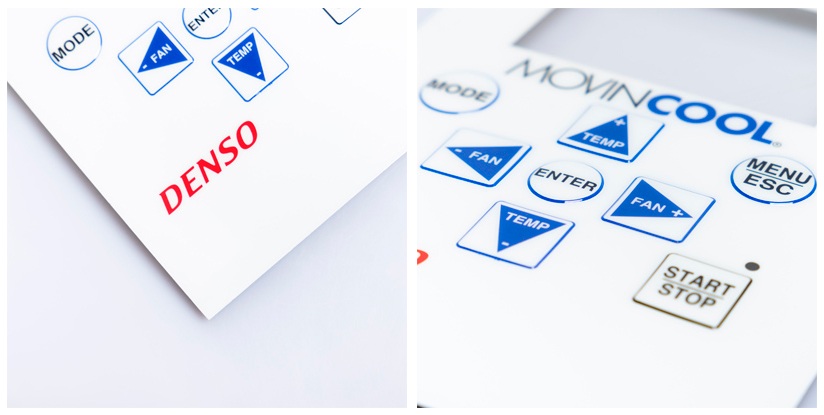

Graphic overlays serve as the crucial interface between a user and a device. Whether on a control panel, a dashboard, or an electronic product, the materials chosen for these overlays are paramount. In this guide, we delve deep into the world of graphic overlay materials, their unique properties, and how to choose the best ones for your specific needs.

A graphic overlay not only imparts visual appeal but also ensures functionality and durability. Three critical elements come into play:

The foundation of any graphic overlay is its substrate. The choice of material impacts its longevity, feel, and appearance.

Polycarbonate and Polyester are two leading choices:

Polycarbonate: Offers excellent clarity, dimensional stability, and is highly resistant to impact. Suitable for high-traffic areas and places prone to wear and tear.

Polyester: Boasts superior chemical resistance, does not yellow over time, and offers an extended lifespan. It's the go-to choice for environments with exposure to chemicals or extreme conditions.

Adhesive layers ensure the overlay sticks firmly to its intended surface. The choice of adhesive can vary based on:

Application surface (e.g., metal, plastic, glass)

Environmental factors (e.g., exposure to UV rays, moisture, chemicals)

Operational demands (e.g., frequent user interaction)

Overlays can come in various finishes, each offering its aesthetic and functional advantages:

Matte: Reduces glare, offers a subdued look.

Glossy: Provides a shiny finish, enhances vibrancy of colors.

Anti-microbial: Prevents the growth of microbes, ideal for healthcare settings.

When selecting materials for electronic graphic overlays, one must consider:

Determine where the overlay will be placed. Outdoor applications demand UV-resistant materials, while indoor settings with heavy user interaction might require wear-resistant options.

If the overlay includes touch buttons or LED indicators, it should have properties that allow for these functionalities without hindrance.

The overlay should complement the overall design of the device. Consider color matching, texture, and finish.

While quality shouldn't be compromised, it's essential to find a material that delivers optimal performance within the set budget.

Over the years, there's been significant evolution in the materials used. Early overlays used basic plastics, but with advances in polymer science, today's overlays are more resilient, vibrant, and versatile.

With increasing emphasis on sustainability, materials like bio-based plastics are making their way into the market.

Today's overlays come embedded with technologies like Near Field Communication (NFC) chips, offering added functionalities.

In conclusion, the realm of graphic overlays is expansive and dynamic. Understanding the intricacies of material selection can drastically enhance the durability, functionality, and appearance of these crucial interfaces. Whether you're an engineer, a designer, or a product manager, having a deep understanding of the available materials will serve you well in creating products that aren't just functional but also aesthetically pleasing and long-lasting.