In today's fast-paced world, technology continues to advance at a rapid rate, and with it comes the need for more efficient and versatile solutions. One such solution is the PCB membrane switch, a cutting-edge technology that is revolutionizing the way we interact with electronic devices. In this blog, we will explore the advantages of using PCB membrane switches and how they are shaping the future of technology integration.

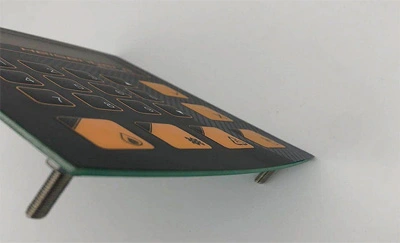

Before we dive into the advantages of PCB membrane switches, let's first understand what they are. A PCB (Printed Circuit Board) membrane switch is a type of user interface that uses a thin, flexible circuit board to control electronic devices. The switch consists of multiple layers, including a top graphic overlay, a spacer layer, a printed circuit, and a backing layer. When pressure is applied to the switch, it activates the circuit and triggers the desired function.

One of the key advantages of PCB membrane switches is their durability. Unlike traditional mechanical switches, which are prone to wear and tear over time, PCB membrane switches are designed to withstand millions of actuations without losing their functionality. This makes them ideal for use in high-demand applications, such as medical devices, industrial equipment, and consumer electronics.

Another advantage of PCB membrane switches is their flexibility and customizability. The graphic overlay can be customized with various colors, textures, and designs to meet the unique requirements of each application. Additionally, the circuit layout can be tailored to accommodate different switch configurations, including tactile feedback, backlighting, and variable actuation force. This level of customization allows manufacturers to create user interfaces that are both aesthetically pleasing and highly functional.

PCB membrane switches are also known for their compact and space-saving design. Unlike traditional switches, which require bulky components and intricate wiring, PCB membrane switches are thin, lightweight, and can be mounted directly onto the surface of a device. This not only reduces the overall size of the device but also simplifies the assembly process and lowers manufacturing costs.

PCB membrane switches are designed to be sealed against dust, moisture, and other environmental contaminants. The layers of the switch are bonded together using adhesive or heat sealing, creating a watertight barrier that protects the circuit from damage. This sealing feature makes PCB membrane switches ideal for use in harsh environments where traditional switches would be vulnerable to corrosion or malfunction.

In conclusion, PCB membrane switches offer a host of advantages that make them an attractive choice for manufacturers looking to improve the functionality and aesthetics of their electronic devices. With their durability, customizability, space-saving design, and sealing capabilities, PCB membrane switches are shaping the future of technology integration and setting new standards for user interface design. As technology continues to evolve, we can expect to see even more innovative applications of PCB membrane switches in a wide range of industries.