Membrane switches are a type of user interface that allows communication between electronic devices and their users. They are made up of multiple layers of flexible material that are printed with circuitry and symbols, and can be customized to meet specific needs. In this article, we will explore the topic of membrane switch customization and how it can benefit various industries.

Membrane switches are used in a variety of industries, from medical devices to aerospace applications, and are often preferred over traditional mechanical switches because they are more durable, cost-effective, and easier to clean.

One of the main benefits of membrane switches china is their ability to be customized to meet specific needs. Customization allows for a unique user experience and can help companies differentiate their products from competitors. Some of the benefits of customization include:

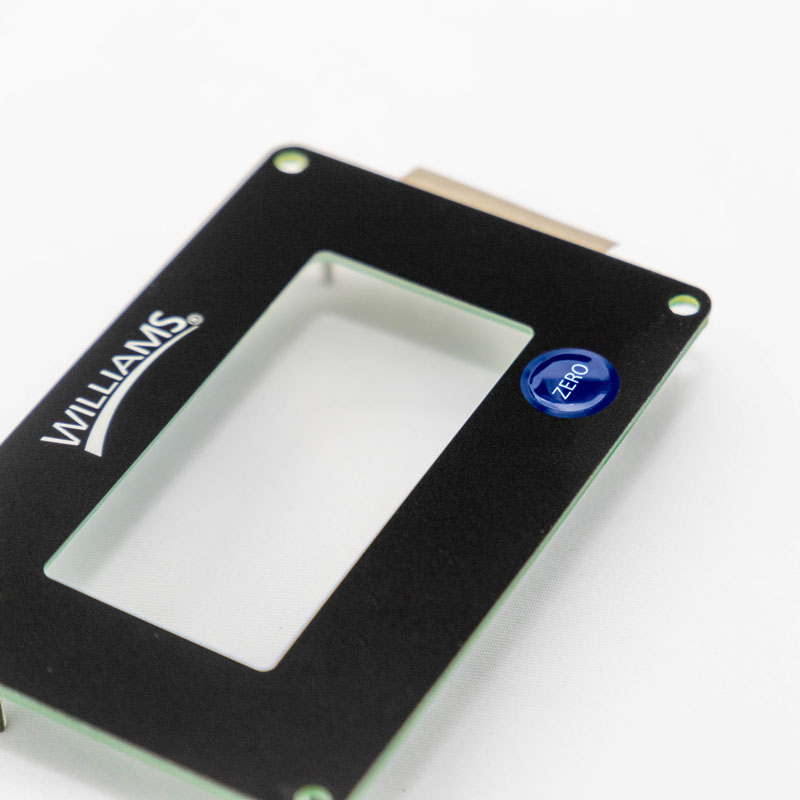

1. Branding and Aesthetics

Customizing a membrane switch with a company's logo or specific color scheme can help enhance brand recognition and create a more cohesive product design. This can also help improve the aesthetics of a product and make it more appealing to potential customers.

2. Improved User Experience

Customization allows for the placement of specific symbols, icons, and text on the membrane switch, which can help guide users through the product's features and functions. This can make the product more user-friendly and increase customer satisfaction.

3. Increased Durability

Customization can also improve the durability of a membrane switch. By selecting the appropriate materials and adhesives, a membrane switch can be designed to withstand harsh environments, extreme temperatures, and frequent use.

When it comes to customization, the possibilities are endless. Here are a few examples of customization options that are commonly used in various industries:

1. Graphic Overlays

Graphic overlays are a printed layer of material that is placed on top of the membrane switch. They can be customized with colors, textures, and graphics to create a unique product design.

2. Backlighting

Backlighting can be used to enhance the visibility of a membrane switch in low light conditions. Custom backlighting options include different colors, intensity levels, and patterns.

3. Tactile Feedback

Tactile feedback is a feature that provides a physical response when the switch is activated. Customizing the tactile feedback can create a specific feel for the user, such as a soft or hard click.

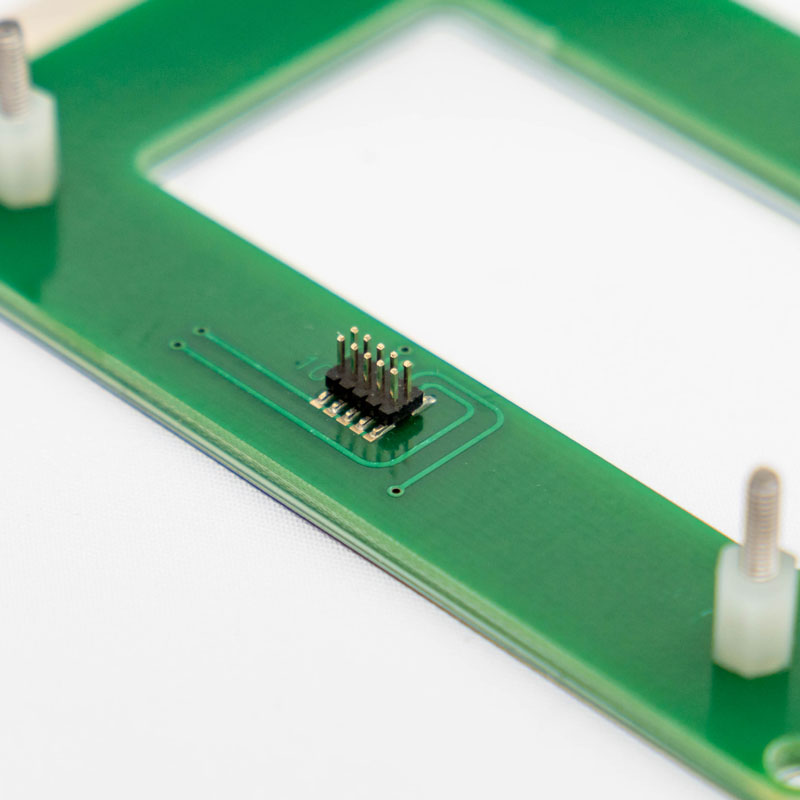

4. Integrated Components

Integrated components, such as LEDs or resistors, can be added to a membrane switch to create additional functionality.

The customization process for membrane switches typically involves the following steps:

1. Design and Engineering

The first step in the customization process is designing the membrane switch. This involves selecting the appropriate materials, determining the circuit layout, and creating the graphic overlay.

2. Prototyping

Once the design is complete, a prototype is created to ensure that the membrane switch functions as intended and meets all specifications.

3. Testing and Certification

The prototype is then tested to ensure that it meets all performance and safety standards. Certification may be required for certain industries, such as medical devices or aerospace applications.

4. Production

Once the prototype is approved, production can begin. The custom membrane switches are manufactured in large quantities and undergo rigorous quality control testing before being shipped to customer

Customized membrane switches are used in a variety of industries and applications, including:

1. Medical Devices

Customized membrane switches are commonly used in medical devices such as patient monitors, infusion pumps, and diagnostic equipment. They are designed to withstand frequent cleaning and disinfecting, and can be customized with specific symbols and text to ensure ease of use for medical professionals.

2. Aerospace and Defense

Customized membrane switches are used in aerospace and defense applications such as cockpit displays, avionics, and communication equipment. They are designed to withstand extreme temperatures and environments, and can be customized with specific backlighting and tactile feedback options for ease of use.

3. Industrial Control Panels

Customized membrane switches are used in industrial control panels for machinery and equipment. They are designed to withstand harsh environments and frequent use, and can be customized with specific symbols, icons, and text to ensure ease of use for operators.

4. Consumer Electronics

Customized membrane switches such as illuminated membrane switch are used in a variety of consumer electronics such as remote controls, gaming consoles, and home automation systems. They can be customized with specific backlighting, tactile feedback, and graphic overlay options to enhance the user experience.

In conclusion, membrane switches can be customized to meet specific needs and offer a range of benefits, including improved branding and aesthetics, enhanced user experience, and increased durability. The customization process involves designing, prototyping, testing, and production, and can result in unique product designs for a variety of industries and applications.

What is the lifespan of a customized membrane switch?

The lifespan of a customized membrane switch depends on the materials and components used, as well as the frequency of use and environmental conditions.

Can membrane switches be customized for outdoor use?

Yes, membrane switches can be customized for outdoor use by selecting appropriate materials and adhesives that can withstand exposure to sunlight, moisture, and extreme temperatures.

Can tactile feedback be customized for different products?

Yes, tactile feedback can be customized for different products by selecting the appropriate dome materials and actuation force.

What is the lead time for customized membrane switches?

The lead time for customized membrane switches depends on the complexity of the design and the quantity ordered, but can range from a few weeks to several months.

Can membrane switches be repaired if they malfunction?

In most cases, membrane switches cannot be repaired if they malfunction and must be replaced. However, regular maintenance and cleaning can help prolong the lifespan of a membrane switch.