Embossing membrane switches, also known as tactile membrane switches, are a critical component in many electronic devices and control panels. These switches provide both functional and aesthetic benefits, making them a popular choice in various industries. In this article, we will delve into the world of embossing membrane switches, exploring their functionality, applications, and advantages.

Introduction to Embossing Membrane Switches

How Do Embossing Membrane Switches Work?

Advantages of Embossing Membrane Switches

Applications Across Industries

Design Considerations

Customization Options

Maintenance and Care

Conclusion

FAQs

Embossing membrane switches are user interface components that consist of multiple layers of flexible materials. They are designed to provide a responsive and tactile feedback when pressed, making them ideal for a wide range of applications. These switches are widely used in industries where reliability, durability, and ease of use are paramount.

Embossing membrane switches function through a simple yet effective mechanism. They consist of several layers, including a top graphic overlay, spacer layers, and a bottom circuit layer. When a user applies pressure to a specific area on the graphic overlay, it flexes and makes contact with the circuit layer beneath it. This contact results in an electrical circuit closure, registering the user's input.

Embossing membrane switches offer several advantages, making them a preferred choice in many applications:

Tactile Feedback: The embossed buttons provide tactile feedback, ensuring that users know when their input is registered.

Durability: These switches are resistant to moisture, dust, and harsh environmental conditions, ensuring longevity.

Cost-Effective: They are often more cost-effective than mechanical switches due to their simplified design.

Customizability: Graphic overlays can be customized with various colors, shapes, and designs.

Space Efficiency: Embossing membrane switches are thin and space-efficient, making them suitable for compact devices.

Embossing membrane switches find applications in numerous industries, including:

Medical Devices: Used in medical equipment like infusion pumps and diagnostic devices.

Automotive: Found in vehicle control panels and dashboard interfaces.

Industrial Control: Utilized in machinery control panels and industrial automation systems.

Consumer Electronics: Present in devices like remote controls and kitchen appliances.

Aerospace: Used in aircraft control panels and navigation systems.

Military and Defense: Employed in ruggedized equipment for military applications.

Designing embossing membrane switches requires attention to detail. Factors such as button layout, labeling, and graphic design play a crucial role in user experience. Engineers and designers must consider the intended application, user interface requirements, and environmental conditions to create an effective design.

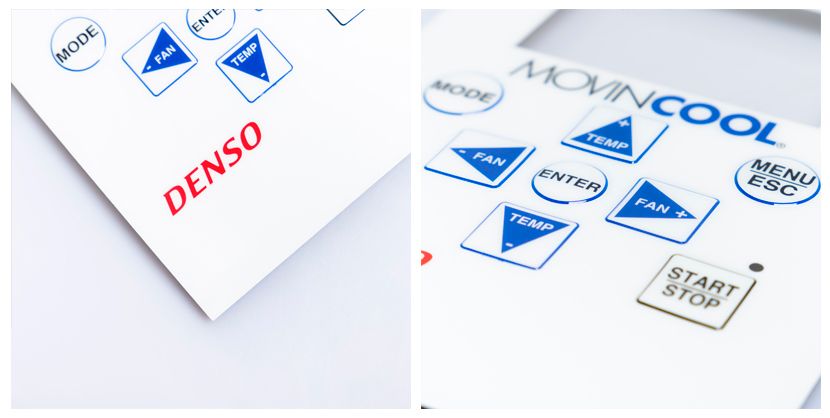

One of the notable features of embossing membrane switches is their customizability. Manufacturers can tailor the graphic overlay to match branding, color schemes, and specific user interface needs. This flexibility allows for the creation of unique and user-friendly control panels.

To ensure the longevity and performance of embossing membrane switches, proper maintenance is essential. Regular cleaning with a mild detergent and soft cloth can help prevent the buildup of dirt or contaminants on the graphic overlay. Additionally, users should avoid using sharp or abrasive objects that could damage the switch.

Embossing membrane switches have revolutionized the world of user interfaces by providing a reliable, durable, and customizable solution. Their widespread use across various industries highlights their versatility and effectiveness. As technology continues to advance, these switches will likely play an increasingly crucial role in our daily lives.

Are embossing membrane switches suitable for outdoor use?

Yes, many embossing membrane switches are designed to withstand outdoor conditions, including exposure to moisture and extreme temperatures.

Can I get embossing membrane switches in custom shapes and sizes?

Yes, manufacturers can produce embossing membrane switches in custom shapes and sizes to meet specific design requirements.

Are embossing membrane switches easy to clean?

Yes, they are easy to clean with a mild detergent and a soft cloth. Avoid abrasive cleaning methods to prevent damage.

Are embossing membrane switches compatible with touchscreens?

They can be used in conjunction with touchscreens to create multifunctional user interfaces in certain applications.

How long do embossing membrane switches typically last?

The lifespan of embossing membrane switches can vary depending on usage and environmental conditions but can last for several years with proper care.

Embossing membrane switches are a vital part of modern technology, offering reliability and functionality in a wide range of industries. Their versatility and customizability make them a top choice for user interface design.