In today's fast-paced world, electronic devices have become an integral part of our lives. From smartphones to microwave ovens, we interact with countless electronic gadgets every day. Behind the smooth operation of these devices lies a crucial component known as a membrane switch. And when it comes to high-quality membrane switches, the LCD Window Membrane Switch Factory stands out as an industry leader. In this article, we'll delve into the world of LCD window membrane switches, exploring their significance, manufacturing process, applications, and much more.

Introduction

Understanding Membrane Switches

The Role of LCD Windows

LCD Window Membrane Switch Factory: A Brief Overview

Manufacturing Process

Quality Control Measures

Applications Across Industries

Customization Options

Advantages of LCD Window Membrane Switches

Challenges and Solutions

Future Trends in Membrane Switch Technology

Why Choose LCD Window Membrane Switch Factory

Conclusion

Frequently Asked Questions (FAQs)

Membrane switches are essential input devices that have found their way into various industries, from medical equipment to automotive dashboards. Among these, LCD window membrane switches are prized for their versatility, durability, and aesthetic appeal. In this article, we'll explore how LCD window membrane switches are manufactured and their wide-ranging applications.

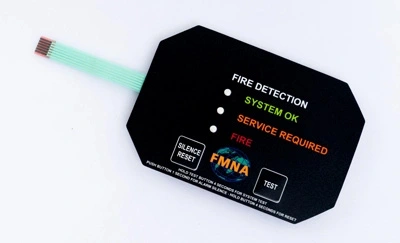

Membrane switches are user interfaces that consist of multiple layers of flexible materials. They typically include graphic overlays, circuit layers, and adhesive layers. These switches are designed to provide a user-friendly and reliable way to control electronic devices.

LCD (Liquid Crystal Display) windows are transparent areas on a membrane switch that allow users to view indicators, displays, or icons on the underlying electronic device. These windows are not only functional but also enhance the overall appearance of the device.

The LCD Window Membrane Switch Factory is a renowned manufacturer specializing in the production of high-quality membrane switches. With years of experience and a commitment to innovation, they have earned a reputation for delivering top-notch products that meet the diverse needs of their clients.

Creating LCD window membrane switches is a meticulous process that involves precise engineering and attention to detail. The factory utilizes cutting-edge technology and materials to ensure the switches meet the highest standards of quality.

Design and Prototyping: Engineers collaborate with clients to design custom membrane switches tailored to their requirements. Prototypes are created for testing and validation.

Material Selection: High-quality materials are chosen to ensure durability and longevity.

Printing and Assembly: Graphics and circuitry are printed onto flexible layers and assembled into a cohesive unit.

Quality Testing: Rigorous testing procedures are in place to verify the functionality and reliability of each switch.

The LCD Window Membrane Switch Factory places a strong emphasis on quality control. Each switch undergoes thorough inspection and testing to ensure it meets industry standards and client expectations. This commitment to quality sets them apart from competitors.

LCD window membrane switches find applications in various industries, including:

Medical: They are used in medical equipment, such as diagnostic devices and patient monitoring systems.

Automotive: Membrane switches are incorporated into car interiors for functions like climate control and audio systems.

Consumer Electronics: Devices like remote controls and kitchen appliances often feature membrane switches.

Industrial Equipment: They play a crucial role in controlling machinery and industrial processes.

One of the key strengths of the LCD Window Membrane Switch Factory is their ability to customize switches. Clients can choose from various options, including different materials, sizes, shapes, and graphic designs, ensuring their specific needs are met.

Durability: They are designed to withstand harsh environments and heavy use.

Aesthetics: The transparent windows enhance the visual appeal of electronic devices.

User-Friendly: Membrane switches offer an intuitive interface for users.

Cost-Effective: They provide a cost-effective solution for user interfaces.

Despite their many advantages, membrane switches face challenges such as wear and tear. However, the LCD Window Membrane Switch Factory continually innovates to address these challenges, ensuring their products remain reliable over time.

As technology advances, membrane switches are expected to evolve as well. The LCD Window Membrane Switch Factory keeps a keen eye on emerging trends, including flexible electronics and touch-sensitive interfaces, to stay at the forefront of the industry.

Clients choose the LCD Window Membrane Switch Factory for several reasons:

Experience: With years of experience, they have honed their expertise.

Quality: Their commitment to quality sets them apart.

Customization: Clients can get switches tailored to their unique requirements.

Innovation: They stay updated with the latest industry trends.

In conclusion, LCD window membrane switches play a pivotal role in modern electronic devices. The LCD Window Membrane Switch Factory's dedication to quality and innovation makes them a trusted partner for businesses across various industries. With their customizable solutions and commitment to staying ahead of the curve, they are shaping the future of membrane switch technology.

Are LCD window membrane switches compatible with all electronic devices?

LCD window membrane switches can be customized to fit the requirements of various electronic devices, making them highly versatile.

How long does it take to manufacture a custom membrane switch?

The manufacturing time varies depending on the complexity and quantity of switches required. The LCD Window Membrane Switch Factory can provide estimated timelines upon request.

What measures are in place to ensure the durability of membrane switches?

The factory employs rigorous quality control measures, including testing for durability and resistance to environmental factors.

Can I get a prototype before placing a bulk order?

Yes, the factory offers prototyping services to ensure the switch meets your specifications before mass production.