Membrane switches are an essential component of modern electronic devices, including smartphones, computers, and medical equipment. These switches are made up of several layers of materials, each with a unique property that contributes to the functionality and durability of the switch. In this article, we will explore the different materials used in membrane switches and their functions.

Membrane switches are a vital part of modern technology, with applications in a wide range of industries. These switches are typically found on the surface of electronic devices, providing a tactile interface for users to interact with the device. The functionality and durability of membrane switches are determined by the selection of materials used in their construction.

In this article, we will explore the different materials used in membrane switches, their properties, and their functions. We will also discuss the importance of material selection in the design of membrane switches and their impact on the performance and reliability of the device.

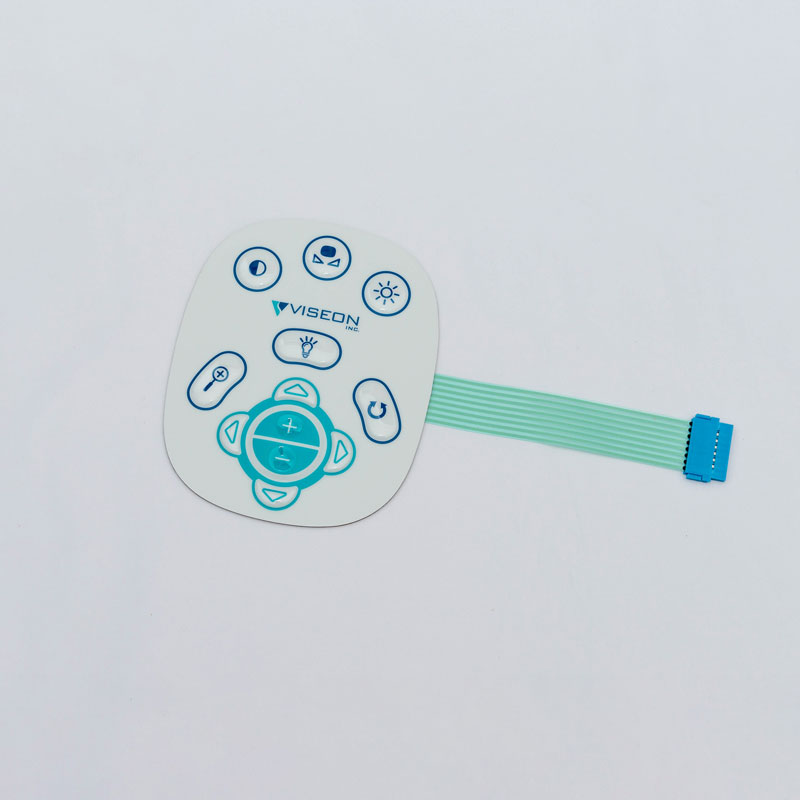

Membrane switches are electronic switches that use a thin, flexible membrane to provide a user interface. These switches consist of several layers of materials that work together to create a tactile interface for users to interact with the device.

Membrane switches are commonly used in a variety of applications, including medical equipment, industrial controls, consumer electronics, and automotive applications. These switches offer several advantages over traditional mechanical switches, including lower cost, reduced size, and increased durability.

Membrane switches consist of several layers of materials, each with a unique function. The basic structure of a membrane switch includes a graphic overlay, adhesive layer, spacer layer, circuit layer, backer layer, and dome switch.

The graphic overlay is the top layer of the membrane switch and provides a tactile interface for users to interact with the device. The adhesive layer is used to bond the graphic overlay to the spacer layer. The spacer layer provides the necessary spacing between the graphic overlay and the circuit layer.

The circuit layer contains the conductive traces that are used to create the switch's electrical connection. The backer layer provides support for the membrane switch and helps to protect the circuit layer from damage. Finally, the dome switch provides the tactile feedback when the switch is pressed.

The materials used in membrane switches are carefully selected to ensure that the switch functions correctly and is durable enough to withstand repeated use. The following is an overview of the materials used in membrane switches:

Graphic Overlay

The graphic overlay is typically made of polyester or polycarbonate material. This layer is responsible for the switch's appearance and provides the tactile interface for users to interact with the device. The graphic overlay can be printed with a variety of graphics, including text, symbols, and logos.

Adhesive Layer

The adhesive layer is used to bond the graphic overlay to the spacer layer. This layer is typically made of acrylic adhesive, which provides a strong bond and is resistant to environmental factors, such as temperature and humidity.

Spacer Layer

The spacer layer provides the necessary spacing between the graphic overlay and the circuit layer. This layer is typically made of polyester material and is available in various thicknesses, depending on the switch's required tactile response.

Circuit Layer

The circuit layer contains the conductive traces that are used to create the switch's electrical connection. This layer is typically made of polyester or polycarbonate material and is coated with a conductive ink, such as silver or carbon. The circuit layer is responsible for the switch's electrical connection and must be able to withstand repeated use without becoming damaged or losing its conductivity.

Backer Layer

The backer layer provides support for the membrane switch and helps to protect the circuit layer from damage. This layer is typically made of polyester material and is available in various thicknesses, depending on the switch's required level of support and protection.

Dome Switch

The dome switch is responsible for providing the tactile feedback when the switch is pressed. This layer is typically made of stainless steel or polyester material and is available in vari ous shapes and sizes, depending on the switch's required tactile response.

The selection of materials used in membrane switches is critical to the performance and reliability of the device. The wrong choice of materials can result in poor switch performance, reduced durability, and a shortened lifespan of the device. Therefore, careful consideration must be given to the selection of materials used in the construction of membrane switches.

For example, the graphic overlay must be able to withstand repeated use without becoming scratched or worn. The adhesive layer must be strong enough to bond the graphic overlay to the spacer layer, while also being resistant to environmental factors, such as temperature and humidity. The spacer layer must be able to provide the necessary spacing between the graphic overlay and the circuit layer, while also providing the required level of tactile response.

The circuit layer must be able to maintain its conductivity even after repeated use, and the backer layer must be able to provide the necessary level of support and protection for the circuit layer. Finally, the dome switch must be able to provide the required level of tactile feedback without becoming worn or damaged.

In conclusion, membrane switches are an essential component of modern electronic devices, and the materials used in their construction play a critical role in their performance and reliability. The careful selection of materials is necessary to ensure that the switch functions correctly, is durable enough to withstand repeated use, and has a long lifespan. Therefore, it is essential to work with qualified and experienced membrane switch manufacturers to ensure that the right materials are selected for the construction of membrane switches.

What are the most commonly used materials in the construction of membrane switches?

The most commonly used materials in the construction of membrane switches include polyester and polycarbonate for the graphic overlay, acrylic adhesive for the adhesive layer, polyester for the spacer layer, conductive ink for the circuit layer, polyester for the backer layer, and stainless steel or polyester for the dome switch.

Can different materials be used in the construction of membrane switches?

Yes, different materials can be used in the construction of membrane switches depending on the switch's required performance and durability.

What factors should be considered when selecting materials for the construction of membrane switches?

Factors that should be considered when selecting materials for the construction of membrane switches include the switch's required performance and durability, the environmental factors the switch will be exposed to, and the required level of tactile response.

What are some advantages of using membrane switches over traditional mechanical switches?

Some advantages of using membrane switches over traditional mechanical switches include lower cost, reduced size, increased durability, and the ability to provide a tactile interface for users to interact with the device.

Can membrane switches be customized to fit specific applications?

Yes, membrane switches can be customized to fit specific applications by selecting the appropriate materials and construction methods to meet the switch's required performance and durability. The use of membrane switches in various industries continues to grow due to their flexibility, cost-effectiveness, and versatility. With advancements in technology and materials, membrane switches can now be customized to meet the specific requirements of different applications. Therefore, it is essential to understand the different materials used in the construction of membrane switches and their functions to ensure that the custom membrane switches function correctly and are durable enough to withstand repeated use.

When selecting materials for the construction of membrane switches, it is essential to consider factors such as the switch's required performance, durability, environmental factors, and required level of tactile response. Working with an experienced and qualified membrane switch manufacturer is also necessary to ensure that the right materials are selected and that the switches are designed and constructed to meet the specific requirements of the application.

In summary, membrane switches are an essential component of modern electronic devices, and the materials used in their construction play a critical role in their performance and reliability. The careful selection of materials is necessary to ensure that the switches function correctly, are durable enough to withstand repeated use, and have a long lifespan. By understanding the different materials used in the construction of membrane switches, their functions, and how they interact with each other, manufacturers can design and construct switches that meet the specific requirements of different applications, thereby ensuring the success of the devices they are used in.