In today's fast-paced technological landscape, the demand for efficient and user-friendly electronic interfaces has never been higher. Adhesive membrane switches have emerged as a versatile and indispensable component in the world of modern electronics. These switches not only provide seamless functionality but also offer a sleek and space-saving design. In this article, we will explore the fascinating world of adhesive membrane switches, from their construction to their myriad applications.

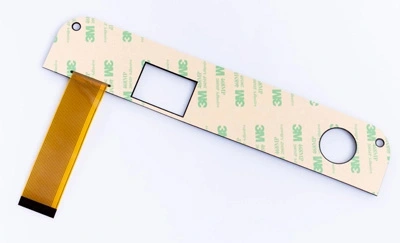

Adhesive membrane switches, often referred to simply as membrane switches, are a type of interface that uses pressure-sensitive adhesive to connect and control electronic devices. These switches consist of multiple layers, each serving a specific purpose. Let's dive into the anatomy of a membrane switch.

Overlay Layer: This is the topmost layer and is usually made of polyester or polycarbonate. It features printed graphics and labels that indicate the functions of each switch.

Spacer Layer: Beneath the overlay layer lies the spacer layer, which contains holes or cutouts aligned with the switch locations. This layer acts as an insulator.

Circuit Layer: Below the spacer layer, there's a circuit layer made of conductive material, typically silver or copper. It contains the electrical traces and contacts required for the switch to function.

Rear Adhesive Layer: The rear adhesive layer adheres the membrane switch to the surface of the device or equipment. It is usually pressure-sensitive and can be customized for different adhesion requirements.

When pressure is applied to a specific area on the overlay layer, it causes the circuit layer to make contact, completing an electrical circuit and activating the intended function. This simple yet effective mechanism makes membrane switches highly responsive and reliable.

The versatility of adhesive membrane switches makes them suitable for a wide range of industries and applications. Here are some notable examples:

1. Medical Devices

Adhesive membrane switches are commonly used in medical equipment, such as diagnostic devices and infusion pumps. Their easy-to-clean surfaces and sealed design make them ideal for maintaining hygiene in healthcare settings.

2. Industrial Control Panels

In industrial settings, where control panels are exposed to harsh conditions, membrane switches provide durability and resistance to environmental factors like dust and moisture. They are widely used in manufacturing machinery and process control systems.

3. Consumer Electronics

From microwave ovens to remote controls, adhesive membrane switches are found in many consumer electronics. Their sleek and customizable designs contribute to the aesthetics of these devices.

4. Aerospace and Automotive

The aerospace and automotive industries rely on membrane switches for their reliability and ability to withstand extreme temperatures and vibrations. They are integral components of cockpit controls and vehicle dashboards.

Let's explore some of the key advantages that make adhesive membrane switches a preferred choice in various applications:

1. Compact Design

The slim profile of membrane switches allows for space-saving designs, making them valuable in devices with limited real estate.

2. Customizability

Membrane switches can be tailored to match the design aesthetics and functional requirements of the device they are integrated into. Custom graphics, backlighting, and tactile feedback can be added to enhance user experience.

3. Durability

With no moving parts, membrane switches are highly durable and resistant to wear and tear, ensuring a long operational life.

4. Cost-Effective

Compared to traditional mechanical switches, membrane switches are cost-effective to manufacture, making them an economical choice for mass-produced electronics.

As technology continues to evolve, adhesive membrane switches are likely to see further advancements. Manufacturers are constantly working on improving their tactile feedback, sensitivity, and resistance to environmental factors. These innovations will only broaden their applications in various industries.

In conclusion, adhesive membrane switches have revolutionized the world of electronics with their versatility, reliability, and sleek design. From medical devices to consumer electronics, these switches have found their way into countless applications. Their future looks promising as they continue to adapt to the ever-changing demands of modern technology.

Are membrane switches waterproof?

Yes, membrane switches can be designed to be waterproof, making them suitable for use in environments where moisture is a concern.

Can I customize the appearance of a membrane switch for my product?

Absolutely! Membrane switches can be fully customized with graphics, colors, and even backlighting to match your product's design.

Are membrane switches easy to clean and maintain?

Yes, their sealed design makes membrane switches easy to clean and maintain, making them suitable for applications in healthcare and food industries.

How long do membrane switches typically last?

Membrane switches are known for their durability and can last for millions of actuations, ensuring a long lifespan for your equipment.

Do membrane switches work in extreme temperature conditions?

Yes, membrane switches are designed to operate in a wide range of temperatures, making them suitable for aerospace and automotive applications.