In the world of modern electronics, where sleek design, functionality, and user-friendliness reign supreme, the humble membrane button switch plays a crucial but often overlooked role. This article will delve into the fascinating world of membrane button switches, exploring their evolution, applications, advantages, and why they are an integral part of many electronic devices.

1. Introduction

2. Understanding Membrane Button Switches

What is a Membrane Button Switch?

The Anatomy of a Membrane Button Switch

3. Evolution of Membrane Button Switches

Early Origins

Technological Advancements

4. Applications of Membrane Button Switches

Consumer Electronics

Industrial Equipment

Medical Devices

5. Advantages of Membrane Button Switches

Durability

Design Flexibility

Cost-Effectiveness

6. How Membrane Button Switches Work

The Mechanism Behind the Click

Tactile vs. Non-Tactile Switches

7. Design Considerations

Choosing the Right Membrane

Customization Options

8. Membrane Button Switches in Everyday Life

Membrane Switches in Home Appliances

Membrane Keyboards

9. Challenges and Maintenance

Common Issues

Maintenance Tips

10. The Future of Membrane Button Switches

Advancements in Materials

Integration with Emerging Technologies

11. Conclusion

12. FAQs

Q1: Are membrane button switches waterproof?

Q2: Can I repair a damaged membrane button switch?

Q3: What is the lifespan of a membrane button switch?

Q4: Are membrane switches eco-friendly?

Q5: How do membrane button switches differ from traditional mechanical switches?

The world of electronics is constantly evolving, with a relentless pursuit of innovation and user experience. Amidst the flurry of high-tech components and cutting-edge devices, the membrane button switch quietly but effectively plays its part. These unassuming switches are present in almost every electronic gadget you interact with daily, from microwave ovens to remote controls, and even in medical equipment.

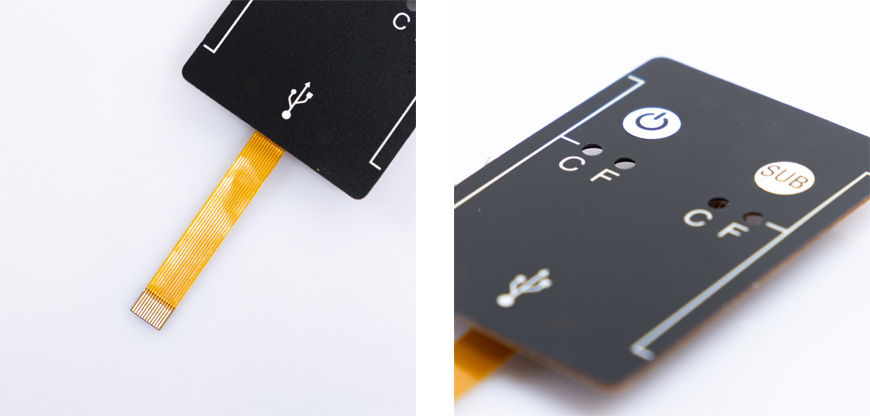

A membrane button switch, also known as a membrane switch or keypad, is a low-profile, flexible electronic switch used to complete an electrical circuit when pressed. It consists of multiple layers of flexible materials, typically including a top graphic overlay, a spacer layer, and a bottom circuit layer.

Graphic Overlay: The top layer features printed symbols or labels, providing a visual guide to the user.

Spacer Layer: This layer separates the top graphic overlay from the bottom circuit layer.

Circuit Layer: The bottom layer contains the circuit traces, which register key presses when contact is made.

Early Origins

Membrane button switches have been around since the mid-20th century. They were initially developed for military applications, where their sealed design and durability were highly advantageous.

Technological Advancements

Over the years, membrane switches have evolved significantly. Modern designs offer improved tactile feedback, greater reliability, and enhanced aesthetics, making them suitable for a wide range of applications.

Consumer Electronics

In consumer electronics, membrane switches are ubiquitous. They are found in remote controls, microwave ovens, and various home appliances, providing a reliable and cost-effective interface for users.

Industrial Equipment

Industrial equipment relies on membrane switches for their durability and resistance to harsh environments. They are used in control panels, manufacturing machines, and even aerospace applications.

Medical Devices

In the medical field, membrane button switches are crucial for equipment like medical monitors and diagnostic devices. Their easy-to-clean surface and reliability are vital in healthcare settings.

Durability

One of the primary advantages of membrane button switches is their durability. They can withstand millions of presses without failure, making them ideal for applications where reliability is paramount.

Design Flexibility

Membrane switches offer unparalleled design flexibility. Manufacturers can customize the graphic overlay, creating a visually appealing and user-friendly interface.

Cost-Effectiveness

Compared to traditional mechanical switches, membrane button switches are cost-effective to produce, making them an attractive choice for manufacturers seeking to keep production costs down.

The Mechanism Behind the Click

Membrane switches can be categorized into tactile and non-tactile switches. Tactile switches provide feedback in the form of a noticeable click or snap when pressed, enhancing the user experience.

Tactile vs. Non-Tactile Switches

Tactile switches are preferred in applications where precise input is required, such as in computer keyboards, while non-tactile switches find use in devices like microwave ovens.

Choosing the Right Membrane

Selecting the appropriate membrane material is essential to meet the specific requirements of each application. Factors like resistance to chemicals, temperature, and UV exposure are critical considerations.

Customization Options

Manufacturers can customize membrane switches with various features, including backlighting, embossing, and integration with other components, to enhance their functionality and aesthetic appeal.

Membrane Switches in Home Appliances

Many home appliances, such as washing machines and coffee makers, rely on membrane button switches for their user interfaces. Their sealed design also makes them easy to clean.

Membrane Keyboards

The keyboard you use daily may feature membrane switches. These keyboards offer a quieter typing experience while maintaining durability.

Common Issues

While membrane button switches are reliable, they can occasionally face issues like wear and tear or contamination. These issues can be resolved through proper maintenance or replacement.

Maintenance Tips

Keeping membrane switches clean and free from debris is essential for their longevity. Regular cleaning with a soft cloth and gentle cleaning agents can help prevent issues.

As technology advances, membrane button switches are expected to evolve further. Advancements in materials and integration with emerging technologies, such as flexible displays, will expand their applications.

The membrane button switch, often hidden beneath the surface of our electronic devices, plays an indispensable role in our daily lives. Its durability, design flexibility, and cost-effectiveness make it an integral component of modern electronics.

Are membrane button switches waterproof?

Yes, many membrane button switches are designed to be waterproof, making them suitable for applications where exposure to moisture is a concern.

Can I repair a damaged membrane button switch?

Repairing a damaged membrane button switch can be challenging and may not always be cost-effective. It's often more practical to replace the switch if it's malfunctioning.

What is the lifespan of a membrane button switch?

The lifespan of a membrane button switch can vary depending on factors like usage and environmental conditions. However, they are known for their durability and can typically withstand millions of presses.

Are membrane switches eco-friendly?

Membrane switches are considered eco-friendly because they can be produced using recyclable materials, and their durability reduces the need for frequent replacements.

How do membrane button switches differ from traditional mechanical switches?

Membrane button switches are typically thinner, quieter, and more cost-effective than traditional mechanical switches. They rely on a different mechanism to register key presses and offer greater design flexibility.