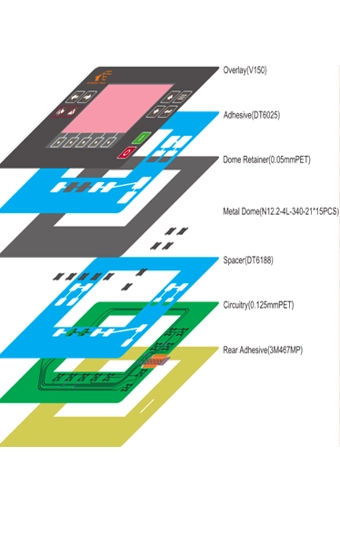

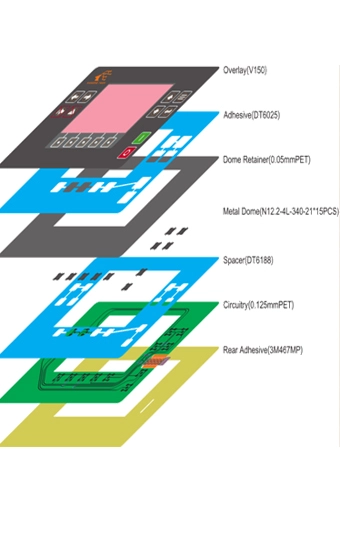

Overlay-Polyester is usually the first choice for membrane switch panel materials because its life will be a little longer than Polycarbonate. If it is simply a panel instead of a membrane switch, Lexan and Polyester are also good choices. The overlay is the most intuitive form of the human-machine interface. Niceone-tech will screen print or digital print on the back of the material, and they can also be used in combination. Special requirements such as the mirror silver effect are also feasible.

English

English français

français Deutsch

Deutsch Español

Español italiano

italiano português

português dansk

dansk Suomi

Suomi Polska

Polska Svenska

Svenska Nederland

Nederland