Polyvinyl chloride (PVC) is stable to acids, alkalis, and salts at room temperature. Good abrasion resistance, flame-retardant self-extinguishing, noise reduction and shock absorption, and good electrical insulation. Poor thermal stability.

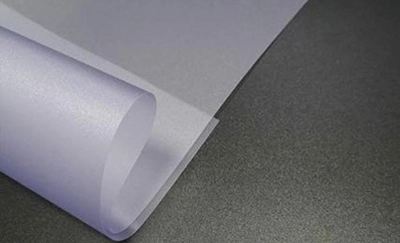

Sand surface polyester (PET), good chemical resistance, insoluble in general organic solvents, not resistant to alkali. It has excellent mechanical properties, electrical properties, rigidity, hardness, and maximum toughness among thermoplastics, low water absorption, excellent wear resistance and friction resistance, and high dimensional stability. The tensile strength is comparable to aluminum film, which is much higher than PC and PVC. Low-cost Because the surface is difficult to process into a matt type, textured PET is more expensive. It is the most ideal substrate for making membrane switch circuits. Among them, textured PET is suitable for products with high surface requirements or with liquid crystal display windows.

Polycarbonate (PC), high light transmittance, low water absorption, good dimensional stability, excellent bending, tensile and compressive strength, excellent heat resistance, cold resistance, electrical insulation, and atmospheric aging resistance. Poor chemical resistance, poor fatigue resistance, prone to stress cracking, the output interface terminal circuit is generally printed on carbon material, and there is no protective coating, and it gradually forms a peeling layer due to air oxidation, which eventually leads to an open circuit End of life, this is the most prone to failure of the membrane switch and panel, mainly determined by the environment, regardless of whether it is used or not, the physical damage time is 3-10 years. The general scope of application is the most extensive. In addition to meeting the requirements of most custom membrane switches, the high light transmittance of the smooth PC can also meet the requirements with liquid crystal display windows.