In today's rapidly evolving technological landscape, electrical circuits play a pivotal role in powering and controlling various electronic devices. At the heart of many of these devices lies a crucial component known as a membrane switch. In this comprehensive guide, we will delve into the world of electrical circuits and explore the significance of membrane switches within them.

Electrical circuits form the backbone of modern technology, powering everything from household appliances to advanced medical equipment. An electrical circuit is a closed loop of conductive materials through which electric current flows, allowing devices to function. These circuits can vary in complexity, from simple to highly intricate designs, depending on the device's function. The key components that make up an electrical circuit include a power source, conductors, load, and control mechanisms.

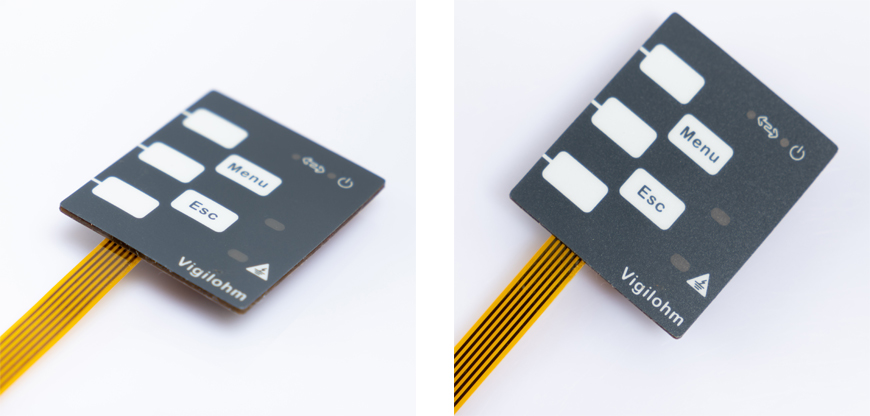

A membrane switch is a type of electrical switch that is both thin and flexible, commonly used to control electrical circuits in various devices. It consists of multiple layers, including a flexible membrane made of materials like polyester or polycarbonate. These switches are designed to be durable, cost-effective, and easy to integrate into electronic devices. The outer layer often features printed graphics for user interaction, such as symbols or labels. When pressure is applied to a specific area on the membrane, it activates the underlying electrical circuit, turning it on or off.

Membrane switches such as waterproof membrane switch are often used in devices where space is limited or where traditional mechanical switches might be too bulky or prone to wear and tear. Common applications of membrane switches include consumer electronics (like microwave ovens and remote controls), medical devices, industrial machinery, and automotive control panels.

A comprehensive understanding of electrical circuits involves familiarity with the components that form them. The primary elements include:

Power Source: The power source, such as a battery or power supply, provides the energy that drives the circuit.

Conductors: Wires or traces that connect components and allow electric current to flow through the circuit.

Resistors: Components that limit or regulate the flow of current, protecting sensitive components from excessive current.

Capacitors: Devices used to store and release electrical energy in the form of an electric field. They play important roles in filtering signals, smoothing power supply outputs, and timing circuits.

Semiconductors: Materials, often in the form of diodes or transistors, that can regulate the flow of electricity in a circuit, allowing for amplification, switching, or signal modulation.

Each of these components has a crucial function in ensuring the circuit operates efficiently and safely. Together, they manage the flow of electricity, ensuring devices perform as intended.

Membrane switches operate through a straightforward yet effective mechanism. The switch is typically composed of several layers: a top layer with printed graphics for user interaction, an insulating spacer layer, and an underlying conductive layer.

When pressure is applied to a particular spot on the membrane, it compresses the layers together, causing the conductive layer to make contact with the circuit beneath. This closes the circuit and allows electric current to flow, turning the device on or triggering a specific function. Once the pressure is released, the layers separate, breaking the connection and opening the circuit.

The design of membrane switches allows them to be both durable and responsive. Because there are no moving parts, membrane switches are less likely to wear out or become damaged over time, making them an ideal choice for devices that require a long lifespan and consistent performance.

Membrane switches are widely used across various industries due to their versatility, durability, and adaptability. Some common applications include:

Medical Devices: In medical equipment such as patient monitoring systems, diagnostic tools, and infusion pumps, membrane switches provide a reliable and easy-to-clean interface for users, especially in environments that require strict hygiene standards.

Consumer Electronics: Membrane switches are commonly found in devices like remote controls, microwaves, and household appliances, where they enable users to interact with the device in a straightforward manner.

Automotive Industry: In automotive controls, membrane switches are used for dashboards, air conditioning systems, and infotainment controls. Their resistance to environmental factors, such as dust and moisture, makes them ideal for use in vehicles.

Industrial Equipment: In industrial settings, membrane switches are used in machines and control panels due to their ability to withstand harsh conditions, such as exposure to oils, chemicals, and extreme temperatures.

Due to their customization options, membrane switches can be designed to fit the specific needs of different applications. They can be tailored in terms of size, shape, graphic design, and the type of response they provide (e.g., tactile feedback or light signals). Their ability to resist environmental factors such as moisture, dust, and chemicals also makes them a preferred choice in a wide range of industries.

Q: What are the main advantages of using membrane switches?

A: Membrane switches offer cost-effectiveness, customizability, durability, and tactile feedback.

Q: Are membrane switches suitable for outdoor applications?

A: Membrane switches can be designed to withstand outdoor conditions, but their suitability depends on specific design considerations.

Q: How do I troubleshoot a malfunctioning membrane switch?

A: Common troubleshooting techniques include checking for physical damage, inspecting connections, and verifying power sources.

Q: What are some notable innovations in membrane switch technology?

A: Innovations include the integration of touch-sensitive interfaces and the use of flexible materials for improved durability.

Q: What does the future hold for membrane switches?

A: The future promises enhanced capabilities and integration into a wider range of electronic devices.