Membrane switches have become a ubiquitous part of our daily lives, found in everything from microwave ovens to sophisticated medical devices. They are prized for their reliability, durability, and versatility. But one critical aspect that determines the functionality and user satisfaction of a membrane switch is its actuation force. So, what is the ideal actuation force for a membrane switch? Let's delve into the mechanics and user experience to find out.

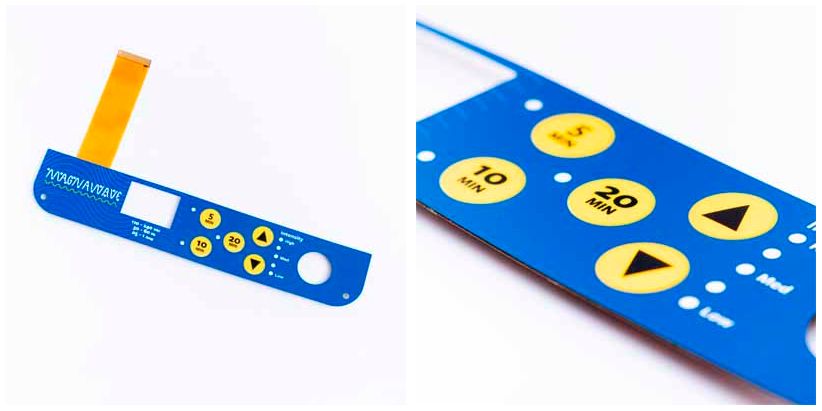

Before we can understand the ideal actuation force, we need to know what a membrane switch is. A membrane switch is a momentary electrical contact on/off switch that activates or deactivates an electric circuit. These are made from a series of flexible layers or "membranes" and have become a preferred user interface for many applications.

Actuation force refers to the amount of pressure required to activate a switch and establish an electrical connection. It plays a significant role in determining how easily a switch responds to user input. The right actuation force is crucial because it directly impacts the tactile feedback, user comfort, and overall performance of the switch. A switch with too little actuation force may be overly sensitive, leading to accidental presses, while a switch that requires too much force can be difficult or uncomfortable to use over extended periods. Properly calibrating actuation force ensures that the switch operates reli

The actuation force of a membrane switch plays a crucial role in determining how a user interacts with the device. It directly affects the tactile feedback and overall user experience. If the actuation force is too light, the switch may activate accidentally, leading to unintentional inputs that could disrupt the operation. On the other hand, if the actuation force is too heavy, it can cause user fatigue or discomfort, particularly in devices that require frequent use. A well-calibrated actuation force ensures that the switch is both responsive and comfortable to use, contributing to the overall effectiveness and user satisfaction.

Several factors contribute to the actuation force of membrane switches:

Material of the Membrane: The materials used in the construction of the membrane, such as polyester or polycarbonate, affect the overall flexibility and response. The material's thickness and stiffness will influence how much force is required to compress the membrane.

Design of the Dome: The dome structure, whether silicone or metal, plays a significant role in determining the actuation force. The size, shape, and thickness of the dome will determine how much pressure is needed to make the electrical contact.

Environmental Conditions: Temperature, humidity, and other environmental factors can alter the materials' properties, which can, in turn, impact the actuation force. For instance, extreme temperatures can make the membrane more rigid, requiring more force to activate.

While the ideal actuation force can vary depending on the application, there is a generally accepted optimal range for most uses. Typically, the actuation force for membrane switches falls between 100g to 500g. For consumer electronics and office devices, a lighter force (around 100g to 200g) is often preferred, ensuring a quick and easy response with minimal user effort. For industrial or medical applications, a slightly higher force (around 300g to 500g) might be more appropriate, as it reduces the likelihood of accidental presses and ensures precise input in more demanding environments.

In industrial settings, the actuation force is especially important for ensuring safety and efficiency. In environments where machinery or equipment is controlled via membrane switches, the actuation force must be calibrated to prevent accidental activation while still being responsive enough for efficient operation. For instance, in heavy machinery or aerospace controls, operators may require switches that offer more resistance to prevent inadvertent errors. Additionally, industrial applications often involve environments with challenging conditions, such as high temperatures, dust, or moisture, which makes selecting the correct actuation force even more critical to maintaining consistent performance. Therefore, careful consideration of actuation force ensures that the switches provide both reliability and safety for operators in these high-stakes settings.

The ideal actuation force for a membrane switch is not a one-size-fits-all answer. It depends on various factors, including the application, user preferences, and environmental conditions. However, by understanding these factors and how they interact, manufacturers can design membrane switches that offer the best balance between sensitivity and resistance, ensuring a positive user experience and reliable performance.