Dive into the world of flexible membrane switches and discover how their versatility can transform the efficiency and resilience of your electronic devices.

Flexibility isn't just a physical attribute; it's a game-changer in the world of membrane switches. This feature goes beyond the mere ability to bend; it encompasses adaptability, resilience, and the capacity to meet diverse application needs. Here, we explore why flexibility is a critical factor when choosing membrane switches, setting the stage for an in-depth understanding of its impact.

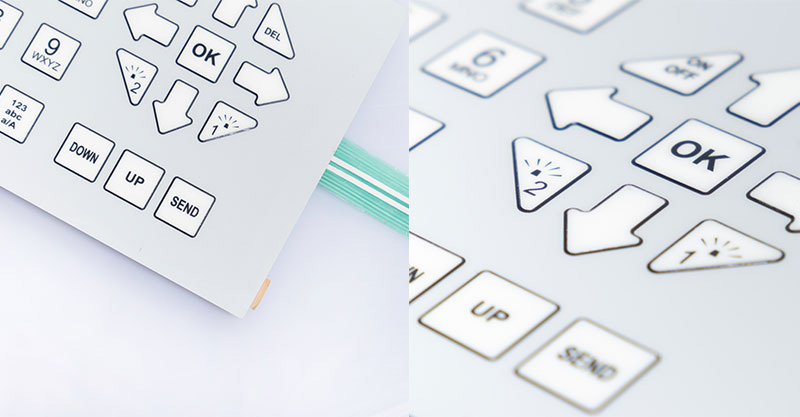

Design Versatility

Flexibility allows membrane switches to be designed in various shapes and sizes, accommodating a wide range of applications. This adaptability is crucial for custom designs where the switch needs to fit into unique or constrained spaces.

Durability and Longevity

Flexible materials used in membrane switches, such as polyester or polycarbonate, are often more durable than rigid alternatives. They can withstand repeated bending and flexing without breaking, which is essential for applications that require frequent use.

Ease of Integration

Flexible membrane switch can be easily integrated into different types of devices, including those with curved or irregular surfaces. This makes them ideal for modern electronics, automotive dashboards, medical devices, and wearable technology.

Cost-Effectiveness

The materials and manufacturing processes used for flexible membrane switches are generally cost-effective. This makes them an economical choice for both low and high-volume production runs, reducing overall manufacturing costs.

Lightweight

Flexibility often comes with a reduction in weight. Lightweight membrane switches contribute to the overall reduction in the weight of the final product, which is particularly important in portable and handheld devices.

Navigating the options available can be overwhelming. Here, we provide a guide on how to select the right flexible membrane switch, considering factors like application environment, required durability, and design specifications. Choosing the right flexible membrane switch for your specific needs involves several key considerations, and working with a reputable supplier like Niceone Tech can make the process smoother and more efficient.

Environment: Consider the environmental conditions where the switch will be used. Factors like temperature, humidity, exposure to chemicals, and UV light can affect the choice of materials. Waterproof flexible membrane switches may be a good choice in some specific situations.

Usage Frequency: Determine how often the switch will be used. High-usage applications may require more durable materials and construction.

Space Constraints: Assess the available space for the switch. Flexible membrane switches are ideal for applications with limited space due to their thin profile.

Tactile Feedback: Decide if you need tactile membrane switches (a noticeable "click" when pressed) or non-tactile membrane switches.

Backlighting: Determine if backlighting is necessary for visibility in low-light conditions. Options include LED, fiber optic, and electroluminescent backlighting.

Integration with Other Components: Consider if the switch needs to integrate with other components like touch screens, displays, or other electronic interfaces.

Overlay Material: Common materials include polyester and polycarbonate. Polyester is generally more durable and resistant to chemicals, while polycarbonate offers better optical clarity.

Adhesives: Choose adhesives that are suitable for the substrate and environmental conditions. High-performance adhesives are available for challenging environments.

Circuit Design: Determine the type of membrane switch circuit you need (e.g., silver printed, copper flex, or printed circuit board).

Connector Type: Choose the appropriate connector type for your application, such as ZIF (Zero Insertion Force), FFC (Flat Flexible Cable), or custom connectors.