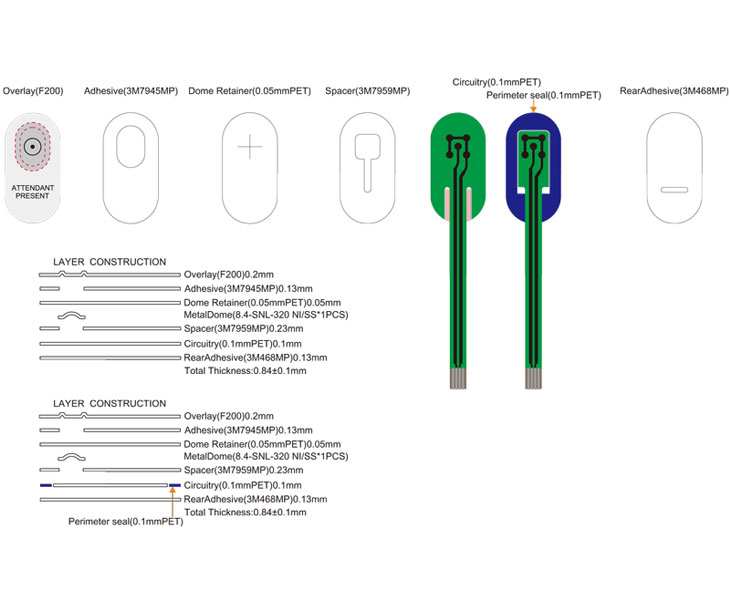

Membrane switch has been used in more and more industries in recent years and is becoming more and more popular. A membrane switch is also an electronic switch made of sheet material and adhesive paper. The internal electrical circuit is generally formed by silver flex membrane switch formed by silver oil and carbon oil circuit or flex membrane switch formed by etched Flex copper or PCB circuit. The rigid membrane switch. is a reliable input device.

One of the reasons why Membrane switch is becoming more and more popular is that its waterproof performance and waterproof design can make some Membrane switches be used underwater. Even in humid environments or areas with plenty of rain, the operator will not have functional problems when using the flexible waterproof membrane.

If the membrane switch is used in marine equipment and medical equipment, which are susceptible to liquid and water pollution, then the electronic components need to be completely sealed with external substances.

Membrane switches can be made waterproof, and under certain conditions, Membrane switches can even be used underwater.

When these conditions are met more, the waterproof effect will be better.

1. It is better to choose adhesive paper or thermal adhesive paper -3M or Nitto with better adhesion.

2. Frame Seal Gasket: Due to the use of the Frame Seal gasket, the liquid cannot enter the circuit through the filler at the tail of the Membrane switch, which makes the product buttons malfunction. The larger the Frame Seal Gasket, the better the waterproof effect. In short, it is the button. The farther the light and line traces are from the edge of the product, the larger the product and the better the waterproof effect.

3. Use Flex copper as the line, so that the line track can be denser, the area is smaller, and the frame seal gasket has more positions to make the waterproof effect better. At the same time, you can click here to learn about the benefits of Using Copper Flex Circuitry vs. Printed Silver

4. Use a silicone rubber keypad as the panel, but its shape needs to be wrap-around.

The answer is 'Yes'. Silicone rubber keypad is an excellent waterproof button product. As long as it is a button-type product, it will be more or less exposed to water or liquid. In order to avoid product functional problems caused by water vapor and liquids, it has always been Niceone-tech's mission to design and produce a silicone rubber keypad with excellent waterproof performance.

The most commonly used scenarios for Waterproof silicone rubber keypad are laboratory, hospital and marine environments. The requirements of these environments for products are more resistant to chemical corrosion and liquid damage to internal components. Therefore, the surrounding design of edge gaskets and silicone rubber keypad can form a completely waterproof seal.

Silicone rubber Keypad is sometimes combined with a membrane switch to form a silicone rubber membrane switch. This type of product needs to have some performance but not limited to it.

1. Superior waterproof performance

2. It is best to choose a waterproof frame structure for the line

3. Choose anti-ultraviolet silicone material

4. Easy to clean

5. Resistance to chemical substances

Even if there are many requirements, the design, aesthetics and usability of the silicone rubber keypad will not be affected. Due to the characteristics of the material, Niceone-tech can customize products of any size and color according to the customer's overture. At the same time, because Silicone rubber keypad is cost-effective, it is one of the reasons why many users choose.

Looking for samples of membrane switch products, or do you want to establish a free design consultation? You can email to info@niceone-tech.com.