Because of the performance and affordable price of membrane switches, membrane switches are now playing an increasingly important role in all walks of life. As long as you pay attention to the fact that membrane switches are everywhere. Many HMI the engineers, designers, or customers are first concerned about the design elements, namely the design on Overlay, which includes color matching, backlight effects, tactile feedback, and embossed effects. Few people will pay attention to the adhesive tape material behind the membrane switch keypad, the brightness of the LEDs, and the wiring. So in order to let customers understand the membrane switch better, we need to introduce the touch keypad membrane switch of the following two structures.

Tape options:

For products sold abroad, Niceone-tech's most commonly used adhesive tape is a 3M adhesive tape, followed by DT adhesive made in China.

Performance:

The performance of 3M waterproof performance, physical and chemical properties will be much better than DT tape

Price:

DT tape will be much cheaper than 3M tape in price. If the customer does not have high requirements for the product, and only needs the price to be more affordable and only for regular use, then DT adhesive tape is also a good choice.

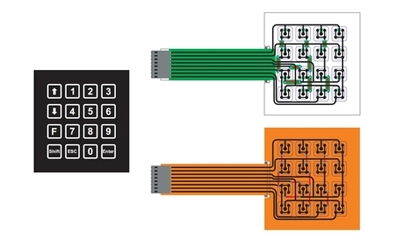

Flex circuit has the most conventional silver flex membrane switch and Copper flex membrane switch. Silver flecks membrane switch is printed on polyester using silver oil, carbon oil, and UV oil (PET) surface forms a complete line. Copper Flex membrane switch is the PI plus copper etching to form a circuit after gold plating. PCB membrane switch is to etch the copper foil on the surface of FR4 and form a solder resist layer with green solder resist oil, but avoid the gold-plated area. Although these names are called differently, they all belong to a membrane switch. The biggest difference is the difference in cost and performance, but the appearance, assembly conditions, and functions of the three are similar.

Layer 1:

The topmost material of the membrane switch is PET or PC, and sometimes it is Silicone Rubber Keypad as a Graphic overlay. Graphic overlay(to change into Graphic Overlay) requires a beautiful appearance, including text, logo, image, etc. Sometimes it is necessary to meet different requirements such as resistance to ultraviolet rays, antibacterial, and scratch resistance.

Layer 2:

The thickness of the tape used is 0.125-0.225 mm, which combines Graphic overlay and Dome Spacer. The choice of adhesive tape will vary depending on the environment and panel material. These will not affect the FPC and PET circuit selection of the membrane switch panel.

Layer 3:

It can be used as the EMI / ESD / RFI shield, the thickness is generally selected 0.05-0.175PET. If the material is too thick, it will affect tactile feedback. Sometimes PI may be selected according to the product. Can also be used as upper line printing ink.

Layer 4:

Thickness is generally 0.175-0.288. Similar to the function of the second layer.

Layer 5:

Niceone-tech believes that the circuit is one of the cores of the membrane panel. The main reason is that Niceone-tech will assemble LEDs, resistors, power supplies, and ICs on the line according to customer requirements. However, the silver flex membrane switch sometimes cannot meet these requirements. At this time, the Copper flex membrane switch can meet these requirements. At the same time, because the wire lines are dense and the product area is small, when the Silver Flex membrane switch cannot meet the electrical performance of the product, the Copper Flex membrane switch is a good choice. However, the Silver Flex membrane switch is very economical in terms of cost. When the Silver Flex membrane switch can meet product requirements, it is a good choice. Because a complete product is marketed, price is sometimes an important factor.

Layer 6:

For the more important layer, different adhesive papers are usually selected based on whether the membrane switch is attached to an aluminum plate or a plastic plate. At the same time, different punching methods on the back of the adhesive tape will have different waterproof effects.

Some customers need to temporarily make less demanding membrane switch products, PET membrane switch is affordable.

The electrical requirements of the customer can be satisfied through the Silver membrane switch. Then it will highly recommend the customer to choose because a good product is a suitable product for the customer, not expensive, it must be Suitable for the customer. Since there are so many advantages of a Silver membrane switch, why sometimes choose a more expensive FPC membrane switch to assemble products?

When the product requires the assembly of a large number of components. Because PET lines cannot be assembled and the performance is unstable, FPC must be selected to meet this requirement.

The product requires lower resistance and higher conductivity. The line of PET is generally less than 150 ohms, but medical or some high-end products are very strict on resistance and conductivity, so FPC is chosen. The resistance of FPC is generally less than 50 ohms.

Use in extreme environments. FPC can withstand extreme environments and use

Prone to silver migration environment. Silver migration will appear from time to time in the Silver flex membrane switch.

The product often vibrates. High-frequency vibrations can cause LEDs or components to fall and result in product failure. Although the welding method of PET is to use glue to fix the components on the line, it is still weaker than the welding strength of FPC.

The product area is small and thin, but there are many functions and circuits to be realized. Sometimes even if the silver oil line bridging, through-hole printing is still unable to achieve the function of the line, we need FPC double panel or multi-panel.

FPC is indeed much more expensive than PET, but the main reason is that it uses a lot of copper and some gold. Since the price of copper and the price of gold will continue to rise in the future, FPC may become more expensive than PET. Depending on the product, the rate of the cost increase is also different. But what can be confirmed is that the stability and reliability of the FPC are worthy of its price. Because the dense lines can be concentrated on a small Copper flex circuit. At the same time, due to the double panel and multi-panel, we can install more accessories in a smaller area, and the product area and volume are smaller. This is an unmatched advantage of PET lines. At the same time, compared with PET, due to the lack of bridging, through-hole printing, the resistance of such products will be smaller. And the ZIF tail of the FPC line can be 0.05 mm apart.

To learn more about membrane switch keypad, please click on the membrane switch product gallery. If you need to customize the membrane switch, please feel free to contact us, our contact information is info@niceone-tech.com.