Membrane switches have become an integral part of our daily interactions with various electronic devices. From microwave ovens to industrial control panels, these versatile components are everywhere. But have you ever wondered about the "feel" of these switches, specifically the force you need to apply to activate them? This force is known as the actuation force, and it plays a crucial role in the functionality and user experience of membrane switches.

Actuation force is the amount of pressure required to activate a switch or key. In the context of membrane switches, it's the tactile response that signals to the user that their input has been registered. This force is not just a matter of user preference; it can affect the speed and accuracy of data entry, and even the longevity of the switch itself.

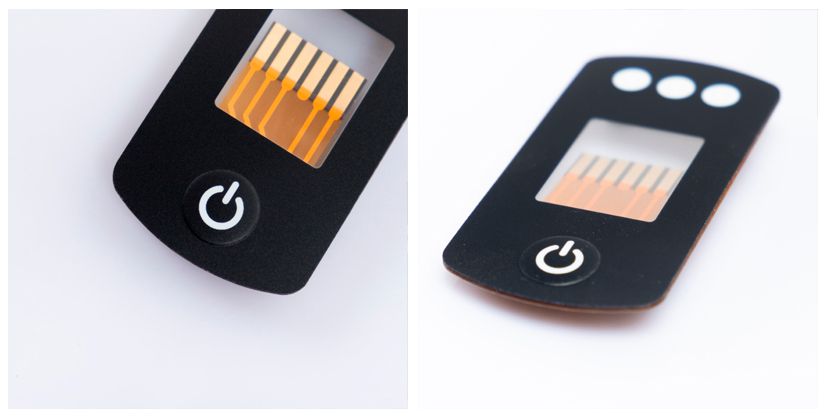

A membrane switch typically consists of several layers, including a graphic overlay, a spacer, and a circuit layer. The actuation force is influenced by the design of these layers and the materials used. For instance, the thickness and elasticity of the spacer can determine how much force is needed to make contact with the circuit layer and trigger a response.

Can the actuation force of a membrane switch be adjusted? The answer is yes, and it can be done with careful design and engineering. The actuation force refers to the amount of pressure needed to activate the switch, and it can be modified during the manufacturing process. This adjustment is typically achieved by altering the materials used in the switch components (such as the membrane layers) or by changing the structural design of the switch, such as modifying the dome shape or thickness of the layers. This ensures that the switch provides the desired tactile feedback and is suitable for the intended application.

Technological advancements have brought about innovative methods for adjusting and measuring actuation force with greater precision. Laser cutting technology, for example, allows for the creation of highly accurate switch components that ensure consistent actuation force across multiple switches. Similarly, digital printing techniques enable the production of highly customizable membrane switches, allowing for more precise control over the materials and features that influence actuation. These advances provide manufacturers with greater flexibility in designing switches that meet specific performance standards.

Customization plays a crucial role in the design of membrane switches, particularly when it comes to adjusting actuation force. Manufacturers can work closely with clients to develop switches that meet unique application requirements. This includes accommodating different tactile preferences, whether users need a softer or firmer press, or designing switches for applications where users may have specific ergonomic needs (such as medical devices or accessibility-focused products). Customization can also involve changes to the visual design, the materials used, and other functional aspects to create the perfect balance of feel, durability, and aesthetics.

Environmental factors such as temperature, humidity, and pressure can have an impact on the actuation force required to operate a membrane switch. For example, extreme temperatures can cause the materials in the switch to expand or contract, altering the feel and response of the switch. High humidity may also affect the flexibility of the membrane, which can change the force needed for activation. To mitigate these issues, designers must take these environmental conditions into account and incorporate materials that maintain consistent performance under various conditions. For example, switches designed for outdoor or industrial use may be made from more robust, temperature-resistant materials, ensuring reliable operation despite environmental fluctuations.

Q: What is the typical range for membrane switch actuation force?

A: The typical range is between 100g to 500g, depending on the application.

Q: Can adjusting the actuation force affect the switch's sensitivity?

A: Yes, adjustments to the actuation force can make the switch more or less sensitive to user input.

Q: Is it possible to adjust the actuation force after the switch has been manufactured?

A: Generally, actuation force is determined during the design and manufacturing process and is not adjustable post-production.

Q: How does actuation force impact the user experience?

A: The right actuation force can enhance the user experience by providing the right balance between sensitivity and resistance, preventing accidental actuation and reducing user fatigue.

Q: Are there any tools available to measure the actuation force of a membrane switch?

A: Yes, there are specialized force gauges and meters that can measure the actuation force of a membrane switch.