The tactile feedback of a dome switch is a crucial aspect of its design, influencing the user experience significantly. This article explores the various factors that can adjust or affect the tactile feedback of dome switches, providing a comprehensive understanding of how these components operate and can be tailored to specific needs.

Tactile feedback refers to the physical sensation a user feels when pressing a dome switch. This feedback is essential for confirming that a keypress has been registered. It's influenced by several design elements within the dome switch.

Types: Common materials include stainless steel, silicone, and polyester.

Effect on Feedback: Metal dome switch provides a crisp, tactile response, while silicone offers a softer feel.

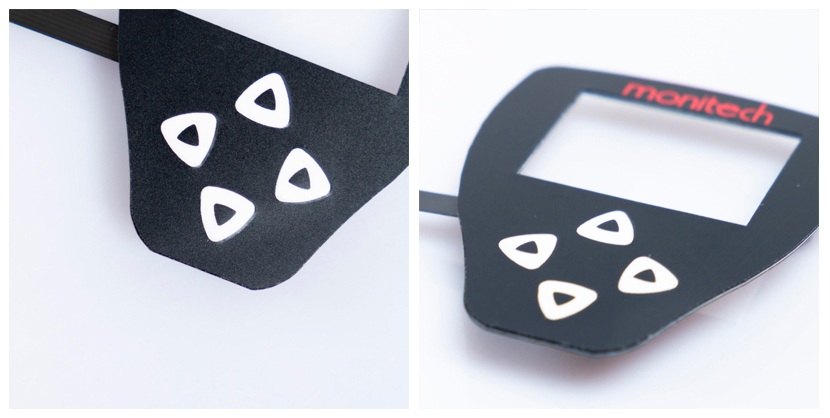

Shapes: Round, four-legged, oblong, etc.

Effect on Feedback: The shape affects the actuation force and travel distance, altering the tactile sensation.

Size Range: Typically, a few millimeters in diameter.

Effect on Feedback: Larger domes can distribute force differently, affecting the feedback. Thicker domes usually require more force to actuate, leading to a firmer feel.

Force Range: Light, medium, and heavy.

Effect on Feedback: The required force to collapse the dome influences how 'hard' or 'soft' the key feels.

Travel Distance: Short or long travel.

Effect on Feedback: The distance the dome travels until actuation impacts the responsiveness perceived by the user.

Types: Single, cross-point, etc.

Effect on Feedback: Different contact designs can change the point at which the circuit is completed, altering feedback.

Materials: Polycarbonate, polyester, etc.

Effect on Feedback: The stiffness and thickness of the overlay material can modify the feedback.

Factors: Temperature, humidity, etc.

Effect on Feedback: Environmental conditions can affect the material properties of the dome and overlay, thus altering tactile feedback.

In dome switches, the material of the dome itself is a key determinant of tactile feedback. Here are some specific materials commonly used:

Stainless Steel: Known for its durability and crisp tactile response.

Nickel Silver: Offers a slightly softer feel than stainless steel but maintains good tactile response.

Silicone Rubber: Provides a much softer feel, suitable for applications requiring a gentle touch.

Polyester Film: Used in thinner, more flexible dome switches, offering a different tactile sensation compared to metal domes.

Each of these materials has unique properties that influence the tactile feedback of the switch.

Material | Durability | Tactile Feedback | Common Uses |

Stainless Steel | High | Crisp, definitive click | High-use applications like keyboards, industrial controls |

Nickel Silver | Moderate | Softer than stainless steel, firm click | Consumer electronics, automotive controls |

Silicone Rubber | Moderate | Very soft, less definitive | Medical devices, devices requiring gentle operation |

Polyester Film | Low | Flexible, soft touch | Lightweight electronics, wearables |