In today's fast-paced world, where technology is evolving rapidly, user interfaces play a pivotal role in enhancing the user experience. One of the innovative technologies that enable efficient and user-friendly interfaces is the FPC (Flexible Printed Circuit) membrane switch. In this article, we will delve into the world of FPC membrane switch factories, exploring their significance, manufacturing process, applications, and more. Join us on this journey to discover how these factories contribute to the creation of cutting-edge user interfaces.

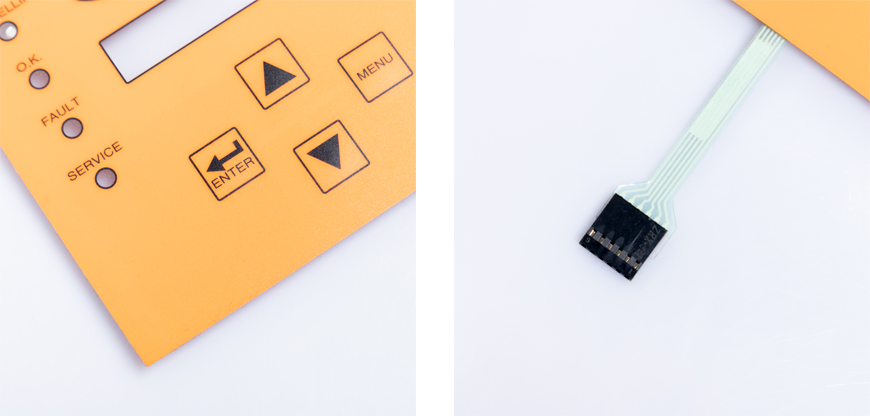

To begin our exploration, let's unravel the fundamentals of an FPC membrane switch. Essentially, it is a user interface component that consists of multiple layers of flexible materials, including polyester and adhesive. These switches are designed to perform various functions, such as sending signals to electronic devices when pressed.

How Does an FPC Membrane Switch Work?

The operation of an FPC membrane switch is intriguing. When you apply pressure to a specific area of the switch, it causes a connection to close, enabling an electrical signal to pass through. This mechanism is the core of many user interfaces we encounter daily.

Now that we have a basic understanding of how FPC membrane switches work, let's delve into why they are essential in today's technological landscape.

1. Durability and Reliability

FPC membrane switches are known for their durability and reliability. They can withstand harsh environmental conditions, making them suitable for various industries, including automotive, medical, and industrial equipment.

2. Customizability

These switches can be customized to fit specific requirements, from the design and layout to the choice of materials. This flexibility is a boon for product designers and manufacturers.

3. Cost-Efficiency

Compared to traditional mechanical switches, FPC membrane switches are cost-effective to produce, making them an attractive choice for businesses looking to reduce manufacturing costs.

Now, let's step into the FPC membrane switch factory to understand how these remarkable devices are manufactured.

1. Material Selection

The process begins with the selection of suitable materials, including polyester, adhesive layers, and conductive inks. The choice of materials depends on the intended application and design.

2. Printing Circuitry

Conductive inks are used to print the circuitry onto the flexible substrate. This step involves precision and expertise to ensure the electrical connections are accurate.

3. Layer Assembly

Multiple layers are stacked and aligned carefully, with adhesive layers bonding them together. This creates a flexible and robust structure.

4. Cutting and Shaping

The assembled layers are cut and shaped according to the desired design, including button placements and circuit paths.

5. Quality Control

Stringent quality control checks are conducted to verify the functionality and durability of each membrane switch.

FPC membrane switches find applications in a wide range of industries, thanks to their versatility.

1. Medical Devices

They are used in medical equipment such as patient monitors and diagnostic devices due to their reliability and ease of cleaning.

2. Automotive

FPC membrane switches are integral components in vehicle dashboards and control panels, ensuring seamless user interaction.

3. Industrial Control Panels

In industrial settings, these switches are employed in control panels to operate machinery and equipment efficiently.

In conclusion, FPC membrane switch factories play a pivotal role in the production of durable, reliable, and cost-effective user interfaces. These switches have revolutionized various industries, making them more user-friendly and efficient. As technology continues to advance, we can expect FPC membrane switches to evolve further, catering to the ever-changing needs of consumers and businesses alike.

Are FPC membrane switches waterproof?

Yes, many FPC membrane switches are designed to be waterproof, making them suitable for outdoor and wet environments.

Can FPC membrane switches be backlit?

Yes, FPC membrane switches can incorporate backlighting to enhance visibility in low-light conditions.

What is the lifespan of an FPC membrane switch?

The lifespan of these switches can vary but is typically in the range of millions of actuations, ensuring long-lasting performance.

Can FPC membrane switches be used in consumer electronics?

Absolutely! FPC membrane switches are commonly used in consumer electronics like remote controls and kitchen appliances.

Where can I find FPC membrane switch manufacturers?

You can find reputable FPC membrane switch manufacturers online or through industry directories. Be sure to research and choose one that suits your specific requirements.