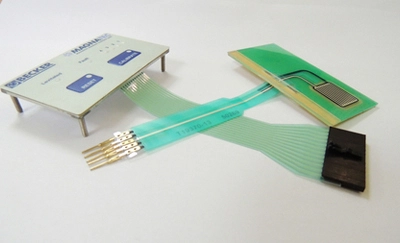

Membrane switches are often combined with some back panels to provide rigidity to electronic and control panels. Membrane switches are sometimes not glued at the bottom but rigid boards such as FR4, AL, stainless steel, acrylic, polycarbonate, and ABS. The important thing is that the size of the membrane switch panel will be slightly larger than the size of the backplate, and it cannot be completely fit. The most commonly used backplate material is AL as the backplate. When Niceone-tech urgently needs the assembly of support plates and panels, our factory can use CNC machines to make them in-house to shorten the processing time. You can even cut extra expenses. AL back panels could be made with flat or formed back panels with holes, studs, or stand-offs.

In order to hide the back panel, its length and width need to be 0.5 mm smaller than the membrane switch panel; punching and cutting need to be 0.75 mm larger than the membrane switch; the size behind the window needs to be 1.5 mm larger. Niceone-tech has a special CNC The machine will process FR4, AL, and other materials, and provide high-quality touch keypad membrane switches with backplanes. I believe our products will make you satisfied.Set your equipment apart from the competition.

Contact Niceone-tech now regarding your user interface assembly. Visit our Membrane Switch Product Gallery to learn more about the various constructions and product features we can offer, and learn how Niceone-tech can customize your membrane switch assembly to meet and exceed your unique application requirements.