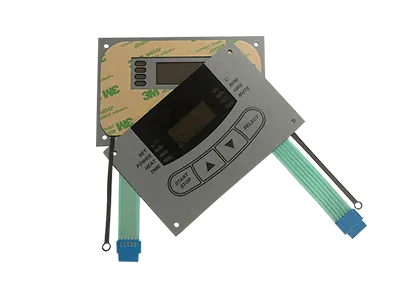

Membrane switches are simply a part of electronic equipment and are often regarded as user interfaces or human-machine interfaces, making it easier for operators to input communications and commands to operate electronic equipment, making users more convenient. A membrane switch can also be called a membrane panel. As a membrane keypad supplier, we also provide a membrane keypad or custom membr ane switches, which is an electrical switches making the circuit turn on or off by changing the key pressure. Generally composed of Polyester, Lexan, Polycarbonate, adhesive, snap dome, connector, conductive inks, carbon ink, or copper flex circuit.

READ MORE

READ MORE

READ MORE

READ MORE

READ MORE

READ MORE

READ MORE

READ MORE

READ MORE

READ MORE

READ MORE

READ MORE

READ MORE

READ MORE

READ MORE

READ MORE

READ MORE

READ MORE

READ MORE

READ MORE

Types of Panel Materials:

The two most commonly used materials for membrane switch panels are polyester and polycarbonate. Both of these materials have their own set of characteristics that make them suitable for specific applications.

Membrane switches are used in a wide range of electronic devices and applications. Here are some common uses of membrane switches:

Consumer Electronics

Industrial Control Panels

Medical Equipment

Automotive

Aerospace and Aviation

ATM and Point-of-Sale (POS) Systems

Military and Defense

Appliance Control Panels

Security Systems

Working Voltage | ≤50V (DC) | Working Current | ≤100mA |

Contact Resistance | 0.5~10Ω | Insulation Resistance | ≥100MΩ (100V/DC) |

Basic Withstand voltage | 2kV (DC) | Loop resistance | ≤50Ω, ≤150Ω, ≤350Ω |

Button Lifetime | >0.5-1.0 million times | Button Stroke | 0.1-1.5mm |

Button Feed BackTime | ≤6ms | Tail Folding | No limit |

Working Temperature | -20℃~+70℃ | Stock Environment | -40℃~+85℃, Sealed |

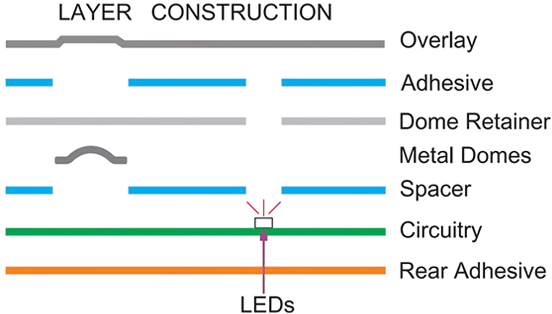

Membrane switches are made of several layers of materials, including a graphic overlay, top circuit layer, spacer layer, bottom circuit layer, and rear adhesive layer.

When you press a key on the membrane switch, it flexes and makes contact with the bottom circuit layer, completing the circuit and sending a signal to the device.

Membrane switches are durable, resistant to contaminants, and easy to clean.

Membrane switches have some limitations in terms of design and are sensitive to extreme temperatures and UV radiation.

Membrane switches are used in various applications, including consumer electronics, industrial equipment, and medical devices.

Niceone-tech customized membrane switches for different customers are widely used in various industries, empowering exceptional product design for other man-machine interface solutions.

Membrane switch constantly updates and upgrade their technology, and their durability is gradually improved. Because of its superior performance and affordable price. As a reliable human-machine interface, it is increasingly favoured by home, office and industrial applications.

Niceone-tech strictly customizes products in accordance with ISO9001-2015 and invests a lot of money every year to develop the technology of the membrane switch to improve the added value of products such as performance, life and function. Our membrane switches are exported in large quantities to European and American countries with stable quality and affordable prices. Niceone-tech understands the standards of European and American countries, so the products are always able to meet and exceed customer expectations.