In today's fast-paced world, technology is advancing at an astonishing rate. With the rise of touchscreen devices and user interfaces, the demand for reliable and durable switches has grown significantly. One essential component in this field is the Rigid Backer Membrane Switch. In this article, we will delve into the key elements that play a crucial role in the design and functionality of these switches.

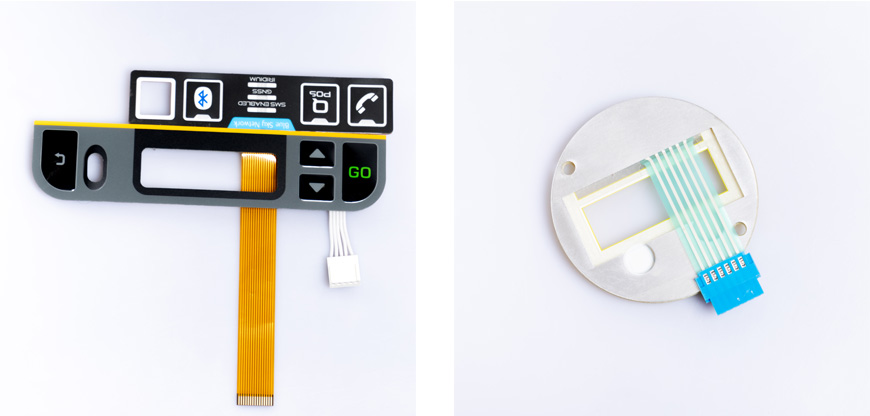

Rigid Backer Membrane Switches are innovative electronic interfaces that have found applications in various industries due to their versatility and reliability. These switches consist of several layers, including a rigid backing material, which serves as a sturdy foundation for the switch components.

The choice of materials is paramount when designing a Rigid Backer Membrane Switch. Different materials offer unique advantages and are selected based on specific requirements.

1. Glass Fiber

Glass fiber is a popular choice due to its durability and resistance to environmental factors. It provides a robust foundation for the switch components.

2. Aluminum

Aluminum is known for its lightweight yet sturdy characteristics. It offers excellent structural integrity and is often used in applications where weight is a concern.

3. Stainless Steel

Stainless steel is chosen for its corrosion resistance and durability. It is a suitable option for switches exposed to moisture or harsh chemicals.

4. Polycarbonate

Polycarbonate is a thermoplastic material known for its lightweight nature and excellent impact resistance. It is frequently used when transparency or backlighting is required.

5. Polyester

Polyester, another thermoplastic material, is valued for its versatility and the ability to effectively accommodate printed graphics and icons.

6. FR-4 (Flame Retardant 4)

FR-4 is an epoxy resin reinforced with glass fiber cloth, offering mechanical strength and flame resistance.

The environmental conditions in which a Rigid Backer Membrane Switch will operate are essential considerations in material selection.

1. Moisture and Chemical Exposure

In environments where the switch may be exposed to moisture, chemicals, or cleaning agents, materials like stainless steel and polycarbonate are preferred. Stainless steel is highly resistant to corrosion, while polycarbonate can withstand exposure to moisture and chemicals.

2. Temperature Extremes

For applications where the switch needs to operate in extreme temperatures, materials with good thermal stability, such as fiberglass and certain plastics, are chosen. Fiberglass and some high-temperature plastics can endure both high and low temperature extremes.

The tactile feedback of a Rigid Backer Membrane Switch can be influenced by the choice of material.

1. Tactile Feedback

Rigid materials like stainless steel or aluminum provide a more substantial and tactile feel when pressed, which can be desirable in applications where the user needs clear feedback.

2. Flexibility

Certain plastic materials like polyester or polycarbonate offer a more flexible feel, which can be preferred in applications where a softer touch is required.

Budget constraints often dictate the choice of material for Rigid Backer Membrane Switches.

Materials like fiberglass and aluminum are generally more cost-effective options, making them suitable for applications where cost is a primary concern.

Let's summarize the advantages and disadvantages of the materials discussed:

Fiberglass

Advantages: Durability, resistance to environmental factors, cost-effective.

Disadvantages: Heavier compared to some plastics, not transparent.

Aluminum

Advantages: Lightweight, sturdy, corrosion-resistant.

Disadvantages: May be more expensive than some other options.

Stainless Steel

Advantages: Corrosion-resistant, durable, provides a tactile feel.

Disadvantages: Heavier and potentially more expensive.

Polycarbonate

Advantages: Lightweight, transparent (suitable for backlighting), resistant to moisture and chemicals.

Disadvantages: Less rigid compared to metals.

Polyester

Advantages: Versatile, can hold printed graphics effectively.

Disadvantages: May not be as durable as some other materials.

FR-4 (Flame Retardant 4)

Advantages: Mechanical strength, flame resistance.

Disadvantages: May be less flexible than some plastics.

The thickness of the backplane also plays a crucial role in the design of Rigid Backer Membrane Switches.

The thickness of fiberglass backplanes typically falls in the range of 0.0625 inches (1.6mm) to 0.125 inches (3.2mm). Thicker fiberglass backplanes offer increased rigidity and durability.

Aluminum backplanes are usually thinner, with thicknesses ranging from 0.020 inches (0.5mm) to 0.125 inches (3.2mm). The choice of thickness depends on the required strength and weight considerations.

Stainless steel backplanes are similar to aluminum in terms of thickness, ranging from 0.020 inches (0.5mm) to 0.125 inches (3.2mm). Thicker stainless steel provides greater durability.

Polycarbonate backplanes are typically thinner, ranging from 0.020 inches (0.5mm) to 0.060 inches (1.5mm). They are chosen for their transparency and flexibility.

Polyester backplanes are generally thin, with thicknesses typically between 0.010 inches (0.25mm) and 0.030 inches (0.75mm). They are valued for their versatility and ability to hold printed graphics.

FR-4 backplanes can have varying thicknesses, usually in the range of 0.031 inches (0.8mm) to 0.125 inches (3.2mm). The thickness choice depends on the required strength and flame resistance.

In conclusion, the selection of materials for Rigid Backer Membrane Switches is a critical decision that impacts the performance and durability of these essential electronic components. Understanding the specific requirements of your application, environmental conditions, tactile feedback, and budget constraints is key to making the right choice.

Whether you opt for the robustness of stainless steel, the flexibility of polycarbonate, or the cost-effectiveness of fiberglass, each material has its advantages and disadvantages. By considering these factors and tailoring your selection to your unique needs, you can ensure the successful operation of your Rigid Backer Membrane Switch.

1. What is the primary function of a Rigid Backer Membrane Switch?

The primary function of a Rigid Backer Membrane Switch is to provide a reliable and user-friendly interface for various electronic devices and control systems. It allows users to input commands or interact with equipment by pressing specific areas on the switch's surface, which then triggers the corresponding actions. These switches are widely used in industries such as medical equipment, aerospace, automotive, and consumer electronics.

2. How does the choice of material impact the performance of a membrane switch?

The choice of material for a membrane switch significantly influences its performance. Different materials offer varying degrees of durability, resistance to environmental factors, tactile feedback, and cost-effectiveness. For instance, stainless steel provides excellent corrosion resistance and a tactile feel, making it suitable for harsh environments. On the other hand, materials like polycarbonate are chosen for their transparency and flexibility, ideal for applications that require backlighting or a softer touch.

3. What are the key factors to consider when selecting a material for a Rigid Backer Membrane Switch?

When selecting a material for a Rigid Backer Membrane Switch, it's essential to consider factors such as the operating environment (moisture, temperature extremes, exposure to chemicals), desired tactile feedback (substantial or flexible), and budget constraints. Additionally, the specific application and its requirements play a crucial role in determining the most suitable material for the switch.

4. Can you provide an example of a real-world application where Rigid Backer Membrane Switches are commonly used?

Certainly! Rigid Backer Membrane Switches are commonly used in the automotive industry for various functions. For example, they are found on the dashboard of vehicles to control functions like climate settings, radio volume, and window operations. These switches provide a durable and user-friendly interface for drivers and passengers, making them an integral part of modern automotive design.

5. Are Rigid Backer Membrane Switches customizable in terms of design and appearance?

Yes, Rigid Backer Membrane Switches are highly customizable in terms of design and appearance. Manufacturers can tailor the switch's layout, graphics, and backlighting to meet the specific branding and functional requirements of their customers. This customization allows for the integration of logos, icons, and user-friendly interfaces that enhance the overall user experience.

In summary, Rigid Backer Membrane Switches are versatile components that play a crucial role in the functionality of various electronic devices and control systems. The choice of materials, environmental considerations, and user preferences all factor into the selection process, ensuring that these switches meet the specific needs of different applications.