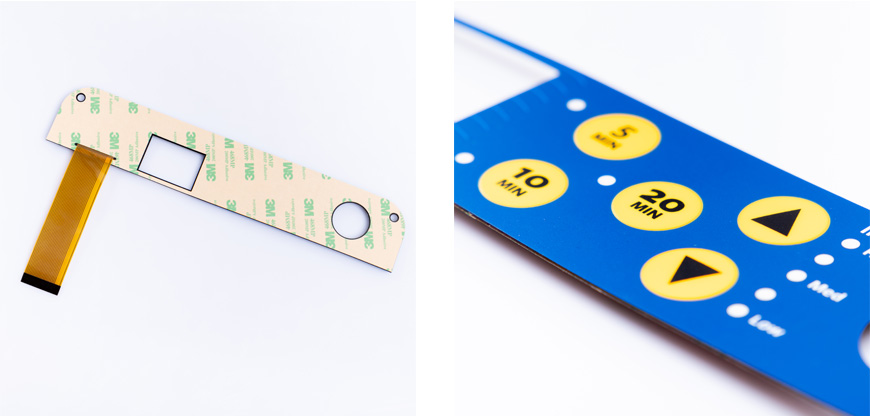

Selective Texturing Membrane Switches have become a game-changer in user interface technology, offering innovative solutions that cater to various industries' needs. These switches utilize specialized coatings, including two primary types: Matte Finish Coatings and Windowed Coatings. In this article, we will explore the significance and applications of these coatings, shedding light on their unique attributes and advantages.

1. Durable Surface

Selective texturing on hard-coated substrates creates a wear-resistant top surface. This durability ensures that the membrane switch can withstand constant use without losing its functionality or appearance.

2. Reduced Glare

The nature of matte finish coatings results in low reflectivity, making text and graphics on the switch easy to read. This feature reduces eye strain and enhances the overall user experience, particularly in environments with varying lighting conditions.

3. Chemical Resistance

Matte finish coatings can act as non-porous barriers, protecting the overlay or panel from the harmful effects of many industrial and household cleaning agents. This safeguards the switch's longevity and performance.

4. Aesthetic Appeal

Combining low reflectivity with high-gloss borders or logos creates an aesthetically pleasing contrast. This visual feature is both effective and visually appealing, often at minimal additional cost.

1. Selective Clarity

Windowed coatings are typically used on textured surfaces, providing areas of clarity or transparency. These clear "windows" allow users to see underlying graphics or indicators while maintaining the textured surface for the rest of the switch.

2. Enhanced Aesthetics

By selectively incorporating windowed coatings, manufacturers can create visually striking interfaces. The combination of textured areas and clear windows results in a unique and appealing user interface design.

3. Protection

Windowed coatings act as protective layers, shielding underlying components from physical damage and environmental factors while maintaining functionality.

4. Cost-Effective Customization

Manufacturers can implement windowed coatings to customize their membrane switches cost-effectively. This allows for tailored designs and branding without compromising durability.

Selective Texturing Membrane Switches find applications across a wide range of industries:

1. Medical Devices

In medical equipment, these switches provide reliable user interfaces with durable surfaces that withstand frequent cleaning and maintain clarity for critical information.

2. Automotive Interfaces

Automobile manufacturers utilize windowed coatings to create visually appealing and functional control panels, combining aesthetics with functionality.

3. Consumer Electronics

In smartphones, remote controls, and gaming devices, matte finish coatings reduce glare and enhance user comfort, while windowed coatings add style and utility.

4. Industrial Controls

Manufacturing and industrial sectors benefit from the durability and customizable design options of these switches for control panels and machinery interfaces.

Selective Texturing Membrane Switches, with their matte finish and windowed coatings, represent a revolution in user interface technology. Their ability to combine durability, aesthetics, and functionality makes them indispensable in various industries. Whether in medical devices, automotive controls, consumer electronics, or industrial equipment, these switches continue to enhance user experiences and offer innovative solutions for user interfaces.

By using these specialized coatings, manufacturers can create switches that are not only visually appealing but also highly functional and resistant to wear and tear, providing users with a reliable and enjoyable interaction with electronic devices.