When moulding silicone rubber products, if the rubber vulcanization temperature is increased, the vulcanization time can be shortened and the vulcanization efficiency can also be effectively improved. Therefore, many vulcanization molding practitioners in the early stage in order to accelerate the moulding speed of custom silicone rubber keypads will start on the increase in vulcanization temperature. Sometimes it does shorten the curing time, but sometimes it's self-defeating, and instead of increasing productivity, there's a whole bunch of numbness and rupture.

Why does this happen? About the rubber vulcanization process

In fact, silicone, and rubber vulcanization temperature cannot indefinitely increase, because of silicone and rubber is a polymers, high temperature can cause the rubber chain output cracking reaction, and crosslink rupture, resulting in " sulfide to return the original " phenomenon, resulting in a decline in the physical and mechanical properties of the silicone, rubber products, namely we often say change and burst. According to the experience accumulated in the production process of some silicone rubber products, Niceone-tech suggests the vulcanization temperature of commonly used silicone and rubber as follows :

Suggestions for vulcanization temperature of natural rubber (NR ): the most reasonable range: 140 ~ 150℃, the highest not exceeding 160℃.

Vulcanization temperatures of butadiene rubber (BR), Isoprene Rubber (IR), and neoprene rubber (CR) are recommended: the most reasonable range: 150 ~ 160℃, the highest not exceeding 170℃.

The vulcanization temperature of SBR and NBR is recommended: the vulcanization temperature can be over 150℃, but the highest is not more than 190℃.

The vulcanization temperature of butyl rubber (IIR ) and ethylene-propylene-diene diene rubber (EPDM ) is recommended: the most reasonable range is 160 ~ 180℃, the highest is not more than 200℃. The thermal vulcanization temperature of silicon rubber (SR ) and fluorine rubber (FR ) is recommended: the most reasonable range is 170 ~ 180℃. If secondary vulcanization is needed, the secondary vulcanization temperature should be controlled at 200 ~ 230℃, and the time should be controlled within 4 ~ 24H according to the process requirements efficiently.

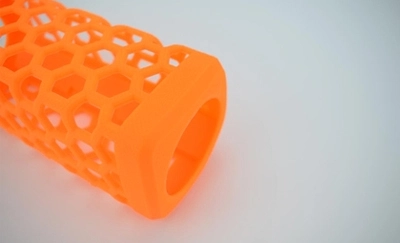

Looking for silicone rubber keypad manufacturers? Niceone-tech is a leading manufacturer of high-quality China rubber keypad, specializing in the production of silicone rubber keypads. If you're in search of silicone rubber keypad manufacturers in China, choose us as your trusted partner. Contact us today to discuss your project and let us provide you with top-notch silicone rubber keypads and membrane keypad that meet your exact specifications.