Meta Description: Learn everything about membrane switches, a widely used technology in electronic devices. Discover their composition, functionality, and applications in this complete guide.

Have you ever used a microwave oven, a TV remote control, or a calculator? If yes, then you have interacted with a membrane switch. Membrane switches are thin, flexible, and durable electronic components that allow users to input commands into electronic devices.

In this article, we will dive into the world of membrane switches, understanding what they are, how they work, and where they are used. Let's get started.

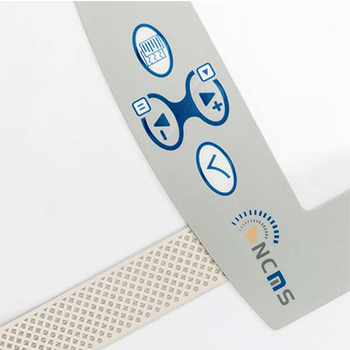

Membrane switches are electronic components made of several layers of materials, including a printed circuit board (PCB), a spacer, a graphic overlay, and a conductive ink. They provide a reliable and cost-effective alternative to mechanical switches, as they offer a soft and quiet operation, while requiring minimal space and power.

Membrane switches can have different configurations, such as tactile, non-tactile, and capacitive. Tactile switches provide tactile feedback when activated, while non-tactile switches do not. Capacitive switches use a touch-sensitive mechanism to detect the presence of a finger, without requiring any physical pressure.

The composition of a membrane switch depends on its type and purpose. However, most membrane switches share the following layers:

Graphic Overlay: The top layer of the membrane switch, which features the printed symbols, text, and graphics that represent the commands that the user can input.

Adhesive Layer: A thin layer of adhesive material that attaches the graphic overlay to the next layer.

Overlay Spacer: A layer that separates the graphic overlay from the top circuit layer, providing a gap for the actuation force.

Top Circuit Layer: A layer of polyester film, which includes the printed circuit that connects the graphic overlay with the bottom circuit layer.

Adhesive Layer: A second layer of adhesive material that attaches the top circuit layer to the bottom circuit layer.

Bottom Circuit Layer: A layer of polyester film, which includes the printed circuit that connects the membrane switch to the electronic device.

Adhesive Layer: A third layer of adhesive material that attaches the bottom circuit layer to the surface of the device.

The functionality of a membrane switch depends on its configuration and design. However, most membrane switches work according to the following principle:

The user applies a force on the graphic overlay, which deforms it and closes the gap with the overlay spacer.

The deformation of the graphic overlay brings the top and bottom circuits in contact, creating an electrical connection.

The electrical connection sends a signal to the electronic device, indicating the input command.

The electronic device processes the signal and responds accordingly, displaying a message, activating a function, or executing a task.

Membrane switches are widely used in various electronic devices and industries, such as:

Medical Devices: Membrane switches are used in medical equipment, such as ultrasound machines, blood analyzers, and ventilators, for their high reliability, ease of cleaning, and resistance to bacteria and fluids.

Consumer Electronics: Membrane switches are used in consumer products, such as remote controls, keyboards, and game controllers, for their low profile, soft touch, and customization options.

Industrial Controls: Membrane switches are used in industrial machinery, such as production lines, robots, and control panels, for their durability, resistance to harsh environments