In today's fast-paced world of technology, the demand for user-friendly interfaces is higher than ever before. Whether you're working on a consumer electronics project, a medical device, or an industrial control panel, one essential component that can greatly enhance user experience is a membrane switch. These thin, flexible, and durable switches are not only easy to integrate but also customizable to suit your specific needs. If you're considering incorporating a membrane switch into your project, this comprehensive guide will help you navigate the process of choosing the right DIY membrane switch supplier.

1. What is a Membrane Switch?

2. Advantages of Using Membrane Switches

3. Applications of Membrane Switches

4. Choosing the Right Membrane Switch Supplier

5. Factors to Consider When Selecting a Supplier

6. Quality Control and Testing

7. Customization Options

8. Pricing and Budget Considerations

9. Lead Time and Manufacturing Capacity

10. Warranty and Support

11. Case Studies: Successful Projects with Membrane Switches

12. DIY Installation and Maintenance

13. FAQs

14. Conclusion

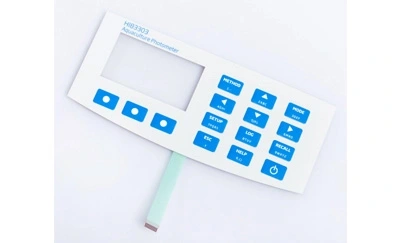

A membrane switch is a user interface device that consists of multiple layers, including a graphic overlay, adhesive spacer, and flexible printed circuit. When pressure is applied to the surface of the graphic overlay, it activates the underlying circuit, registering a keypress. These switches are known for their reliability and versatility.

Durability: Membrane switches are resistant to moisture, chemicals, and physical wear, making them ideal for harsh environments.

Customizability: They can be designed to fit specific shapes, sizes, and functionalities.

Cost-Efficiency: Membrane switches are often more affordable than alternative input methods.

Sleek Design: Their flat, low-profile design is aesthetically pleasing and easy to clean.

Tactile Feedback: Many membrane switches offer tactile feedback, enhancing the user experience.

Membrane switches find applications in various industries, including:

Medical: Used in medical equipment, diagnostic devices, and patient monitoring systems.

Industrial: Commonly found in control panels, industrial machinery, and equipment.

Consumer Electronics: Integrated into remote controls, microwave ovens, and appliances.

Automotive: Used for dashboard controls and infotainment systems.

Aerospace: Utilized in cockpit controls and navigation systems.

Selecting the right DIY membrane switch supplier is crucial to the success of your project. Here are the key factors to consider.

Experience and Expertise

Look for suppliers with a proven track record in manufacturing membrane switches. An experienced supplier is more likely to deliver high-quality products and provide valuable insights.

Reputation and Reviews

Check online reviews and ask for references to gauge the supplier's reputation. Positive feedback from previous customers is a good indicator of reliability.

Certification and Compliance

Ensure that the supplier meets industry standards and certifications relevant to your project. Compliance with regulations is essential, especially in sectors like healthcare and aerospace.

Customization Options

Choose a supplier that offers customization options to match your project's unique requirements. This includes graphic design, material selection, and integration of additional features like backlighting or embossing.

Pricing and Budget Considerations

Obtain quotes from multiple suppliers and compare pricing. Keep in mind that quality should not be sacrificed for cost savings.

Lead Time and Manufacturing Capacity

Consider the supplier's lead times and production capacity. Timely delivery is crucial to project timelines.

Warranty and Support

Inquire about the warranty and after-sales support provided by the supplier. A reliable warranty ensures peace of mind and protection against defects.

A reputable supplier will have rigorous quality control processes in place. Ensure that the switches undergo thorough testing for functionality and durability.

Discuss your project requirements with the supplier to explore customization possibilities. From design aesthetics to button feel, tailoring the membrane switch to your needs is essential.

While cost is a factor, prioritize value over the cheapest option. A higher upfront investment can result in long-term savings through enhanced durability and performance.

Consider your project's timeline and production volume. Choose a supplier that can meet your deadlines and scale production as needed.

Ensure the supplier offers a warranty that aligns with your project's lifespan. Prompt and responsive customer support is also essential for troubleshooting and maintenance.

To illustrate the versatility of membrane switches, here are a few case studies:

Medical Device Interface: A medical device manufacturer improved user interaction with a custom-designed membrane switch that met stringent regulatory requirements.

Industrial Control Panel: An industrial automation company incorporated membrane switches into their control panels, reducing maintenance costs and increasing reliability.

Consumer Electronics: A consumer electronics brand achieved a sleek and modern look for their remote control devices using membrane switches.

Once you've chosen the right DIY membrane switch supplier, proper installation and maintenance are essential for longevity. Follow the supplier's guidelines and consider professional installation for complex projects.

Are membrane switches waterproof?

Yes, membrane switches can be designed to be waterproof, making them suitable for use in wet environments.

Can I design my own graphic overlay for a membrane switch?

Many suppliers offer customization options, allowing you to create a unique graphic overlay for your membrane switch.

How long do membrane switches typically last?

The lifespan of a membrane switch depends on usage and environmental factors but can range from several years to over a decade.

Are membrane switches easy to clean?

Yes, membrane switches are easy to clean and maintain, making them suitable for applications where hygiene is crucial.

Can membrane switches be backlit?

Yes, membrane switches can be designed with backlighting options for improved visibility in low-light conditions.

Choosing the right DIY membrane switch supplier is a critical decision that can significantly impact your project's success. Consider factors such as experience, reputation, customization options, pricing, lead time, and support to make an informed choice. By collaborating with a reliable supplier, you can unlock the full potential of membrane switches for your application.