In today's fast-paced world, technology continues to evolve, and with it, the demand for innovative interfaces and controls. Digital printing membrane switches have emerged as a vital component in various industries, offering a combination of durability, versatility, and aesthetics. In this comprehensive guide, we will delve deep into the world of digital printing membrane switches, exploring their applications, advantages, manufacturing process, and more.

1. Introduction

What are Digital Printing Membrane Switches?

The Importance of Membrane Switches in Modern Devices

2. Understanding Membrane Switch Technology

How Do Membrane Switches Work?

Membrane Switch vs. Mechanical Switch: A Comparison

Types of Membrane Switches

3. Applications of Digital Printing Membrane Switches

Electronics and Consumer Appliances

Medical Devices

Industrial Control Panels

Automotive Industry

Aerospace and Defense

4. Advantages of Digital Printing Membrane Switches

Durability and Longevity

Customization and Design Flexibility

Cost-Effectiveness

Resistance to Environmental Factors

Easy Integration with Electronics

5. The Manufacturing Process

Material Selection

Digital Printing Technology

Embossing and Tactile Feedback

Circuit Layer and Adhesive Assembly

6. Design Considerations

Graphic Overlay Design

Button Layout and Size

Backlighting Options

Integration with Electronics

Environmental Factors

7. Maintenance and Care

Cleaning and Maintenance Tips

Common Issues and Troubleshooting

8. Future Trends in Digital Printing Membrane Switches

Flexible Electronics

Integration of Smart Features

Sustainability Initiatives

9. Conclusion

What are Digital Printing Membrane Switches?

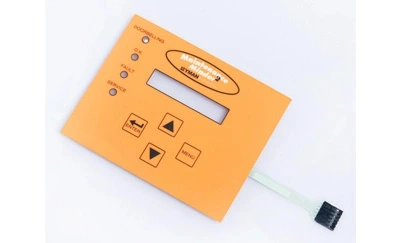

Digital printing membrane switches, often referred to simply as membrane switches, are user interfaces that have become integral to numerous electronic devices and equipment. They consist of multiple layers of flexible materials that work together to provide a tactile and visual interface for users to operate devices.

The Importance of Membrane Switches in Modern Devices

In an era where user experience is paramount, membrane switches play a crucial role. They are commonly found in applications ranging from microwave ovens to medical devices and industrial control panels. The ease of use, customization options, and durability of membrane switches make them an ideal choice for manufacturers and designers.

How Do Membrane Switches Work?

Membrane switches use a simple yet effective principle. When a user presses a button or a part of the switch, it flexes the top layer (graphic overlay) to make contact with the lower circuit layers, completing an electrical circuit and registering the input.

Membrane Switch vs. Mechanical Switch: A Comparison

In contrast to mechanical switches with physical moving parts, membrane switches have no such components. This leads to several advantages, including quieter operation, resistance to dust and moisture, and a longer lifespan.

Types of Membrane Switches

Membrane switches come in various types, each tailored to specific applications. Some common types include tactile membrane switches, non-tactile membrane switches, and capacitive touch membrane switches.

Electronics and Consumer Appliances

One of the most widespread uses of membrane switches is in consumer electronics, such as TV remotes, microwave ovens, and washing machines.

Medical Devices

In the medical field, membrane switches are used in devices like infusion pumps and diagnostic equipment, where hygiene, ease of cleaning, and reliability are essential.

Industrial Control Panels

Industrial control panels rely on membrane switches for their robustness and resistance to harsh environments, making them suitable for factories and manufacturing plants.

Automotive Industry

In automobiles, membrane switches are integrated into dashboards, control panels, and even steering wheels, enhancing both functionality and aesthetics.

Aerospace and Defense

In aviation and defense applications, the reliability and customization options of membrane switches make them indispensable for critical controls and displays.

Durability and Longevity

Membrane switches are designed to withstand millions of actuations, ensuring long-lasting performance even in demanding environments.

Customization and Design Flexibility

Manufacturers can easily customize the appearance and layout of membrane switches to align with their brand or specific user requirements.

Cost-Effectiveness

Compared to traditional mechanical switches, membrane switches are often more cost-effective to produce, reducing overall manufacturing costs.

Resistance to Environmental Factors

Membrane switches are resistant to moisture, chemicals, and extreme temperatures, making them suitable for a wide range of industries.

Easy Integration with Electronics

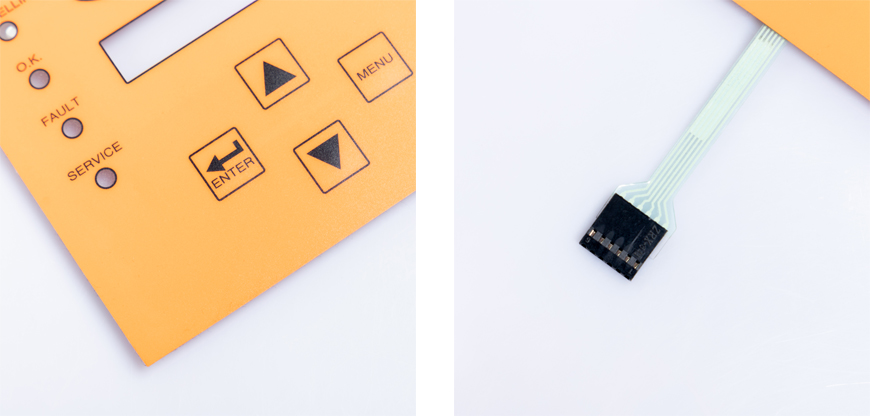

The flat and flexible nature of membrane switches allows for seamless integration with electronic components, simplifying the overall design process.

Material Selection

The choice of materials for each layer of the membrane switch is critical and depends on factors like durability, flexibility, and environmental resistance.

Digital Printing Technology

High-quality graphics and icons are achieved through digital printing, ensuring a visually appealing user interface.

Embossing and Tactile Feedback

Embossing techniques are used to create tactile feedback, providing users with a satisfying click or resistance when pressing buttons.

Circuit Layer and Adhesive Assembly

The circuit layer and adhesive layers are carefully assembled to ensure proper electrical conductivity and adhesion.

Graphic Overlay Design

The graphic overlay is the visible part of the membrane switch and should be designed for clarity, functionality, and aesthetics.

Button Layout and Size

The size and layout of buttons and switches should be user-friendly and consider ergonomic factors.

Backlighting Options

Backlit membrane switches improve visibility in low-light conditions, enhancing the user experience.

Integration with Electronics

Membrane switches are often integrated with microcontrollers and electronics, requiring careful consideration of compatibility and wiring.

Environmental Factors

When designing membrane switches for outdoor or industrial use, environmental factors such as moisture, temperature, and UV exposure must be taken into account.

Cleaning and Maintenance Tips

To prolong the lifespan of membrane switches, regular cleaning and maintenance are essential. Simple cleaning practices can prevent malfunctions.

Common Issues and Troubleshooting

Understanding common issues like ghosting, debouncing, or non-responsive buttons can help users troubleshoot and resolve problems quickly.

Flexible Electronics

Advancements in flexible electronics will likely lead to even more versatile and durable membrane switches.

Integration of Smart Features

The integration of sensors, haptic feedback, and connectivity options will enhance the functionality of membrane switches.

Sustainability Initiatives

Manufacturers are increasingly focusing on sustainable materials and production methods, aligning membrane switch technology with eco-friendly practices.

Digital printing membrane switches have revolutionized the way we interact with electronic devices. Their durability, customization options, and compatibility with various industries make them a fundamental component in modern technology. As we look to the future, we can expect even more innovative